How Much Do You Know About TPO Sheet?

- Share

- publisher

- Polyreflex

- Issue Time

- Nov 22,2022

Summary

As a flexible plastic sheet with excellent thermoforming properties, TPO sheet has been widely used, especially in the auto parts industry. How much do you know about it? Click to learn more.

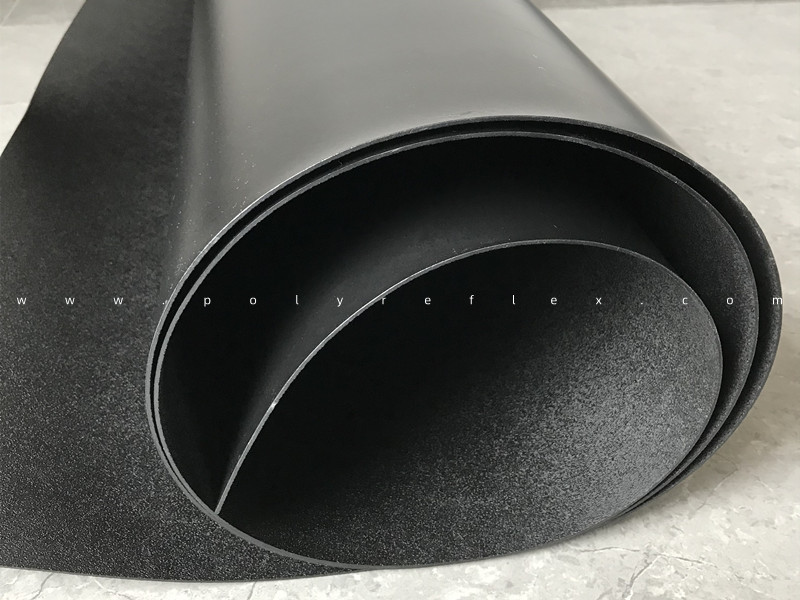

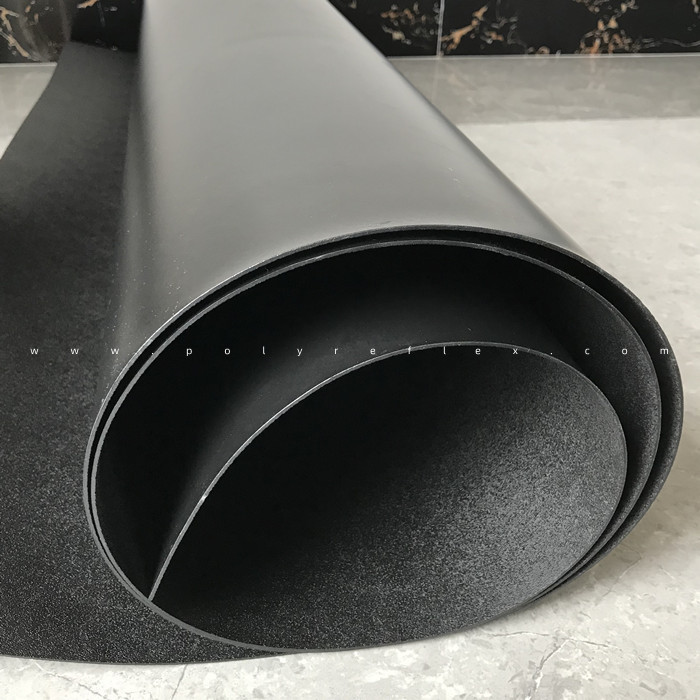

What is TPO sheet?

Compared with PVC material, TPO sheet is lightweight with a density of 0.96g/cm3. TPO combines the performance advantages of EPDM and PVC, has the weather resistance, toughness and flexibility of EPDM, and also has the weldability of PVC.

Its temperature resistance range is minus 60 degrees Celsius to 135 degrees Celsius. TPO sheet is rubbery and highly elastic at room temperature, and can be formed like plastic at high temperature. Therefore, it has good processability and mechanical properties, and has strong welding properties.

TPO products can withstand a variety of adverse elements, such as harsh weather, chemicals, strong vibration and thermal stress.

The main and most popular application field of TPO sheet is auto parts.

In terms of automotive exterior parts, it is mainly used for bumpers, radiators, chassis, body panels, wheel guards, movable roofs and other protective strips, windshield strips, etc. In terms of interior parts, it can be used as instrument panel and door trim panel, outer material of airbag, floor mat, trunk mat, etc.

POLYREFLEX HI-TECH has been a top manufacturer and supplier of PP sheet, PE sheet, ABS sheet, TPO sheet and other thermoplastic sheets in China since its establishment in 2006. We are committed to the development and manufacture of high quality plastic sheet, lightweight polypropylene sheets, including pp corrugated sheet, pp honeycomb board and pp bubble board. If you would like to know more about our products, or to get a quote, please feel free to contact us at sale@polyreflex.com or WhatsApp us at +8613828266785.