FAQs About ABS Sheets

- Share

- publisher

- Polyreflex

- Issue Time

- Sep 6,2023

Summary

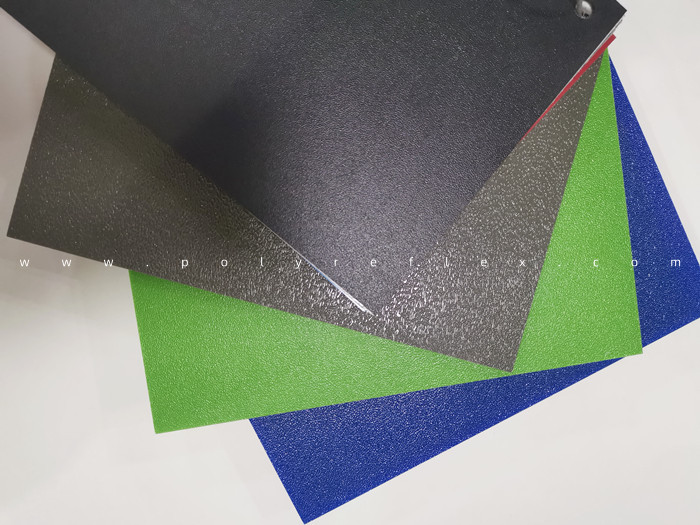

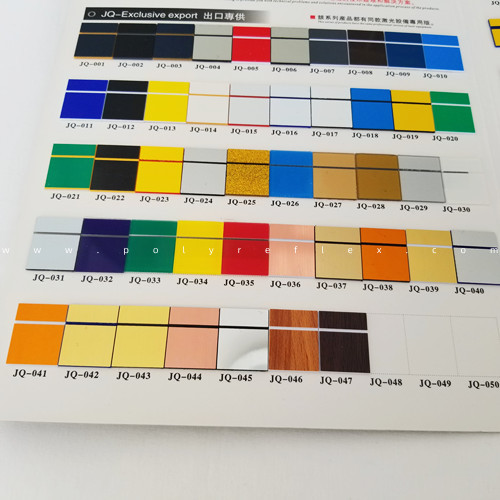

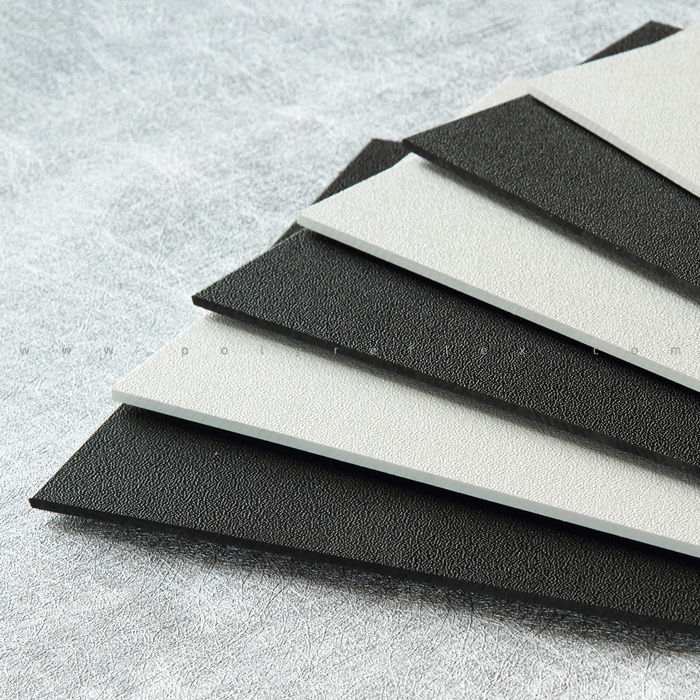

Polyreflex, a leading ABS sheets manufacturer, offers custom solutions for various applications. Explore the benefits, applications, and customization options of ABS sheets. Find reliable and impact-resistant plastics for your specific needs.

Welcome to Polyreflex, your trusted ABS sheets manufacturer and provider of custom solutions. In this comprehensive FAQ guide, we will address the most common questions regarding ABS sheets. Whether you're a DIY enthusiast, an industrial designer, or a manufacturing professional, we've got you covered. Let's dive in and discover everything you need to know about ABS sheets!

Common FAQs About ABS Sheets

Q: What is ABS?

ABS (Acrylonitrile Butadiene Styrene) is a versatile thermoplastic known for its exceptional durability, impact resistance, and heat tolerance. It combines the strength and rigidity of acrylonitrile and styrene polymers with the toughness and elasticity of polybutadiene rubber.

Q: What are the key features of ABS sheets?

- Superior Impact Resistance: ABS sheets can withstand high impact loads, making them ideal for applications that require durability.

- Excellent Temperature Range: ABS sheets offer a wide operating temperature range, typically -20°C to 80°C (-4°F to 176°F), allowing for versatility in various environments.

- Chemical Resistance: ABS sheets exhibit good resistance to many chemicals, including acids, alkalis, and oils.

- Machinability: ABS sheets are easily machined, allowing for precise cuts, holes, and shaping.

- UV Stability: ABS sheets are formulated to resist UV degradation, ensuring long-lasting performance in outdoor applications.

- Electrical Insulation: ABS sheets have good electrical insulation properties, making them suitable for electrical enclosures and components.

Q: What are the typical applications of ABS sheets?

ABS sheets find extensive use in numerous industries, including:

- Automotive: Interior trim, dashboard components, body panels.

- Electronics: Enclosures, housings, control panels.

- Packaging: Cases, containers, protective covers.

- Consumer Goods: Toys, appliances, luggage.

- Medical: Equipment housings, trays, prosthetics.

Q: How can I ensure the best performance of ABS sheets?

To optimize the performance of ABS sheets, consider the following guidelines:

- Avoid prolonged exposure to extreme temperatures outside the recommended range.

- Store ABS sheets in a cool, dry place to maintain their dimensional stability.

- Clean ABS sheets with mild soap and water; avoid harsh chemicals or abrasive cleaners.

- When using ABS sheets outdoors, consider applying a UV-resistant coating for enhanced longevity.

Q: Can ABS sheets be easily fabricated or customized?

Absolutely! At Polyreflex, we offer a wide range of customization options to meet your specific requirements. Our services include:

- CNC Cutting: Precise cuts and intricate designs.

- Laser Engraving: Add logos, serial numbers, or decorative patterns.

- Vacuum Forming: Create 3D shapes and contours.

- Printing: Apply branding, instructions, or graphics.

Q: Are ABS sheets flame retardant?

ABS sheets have a limited flame retardant property. However, for applications that require a higher level of flame resistance, we offer flame-retardant ABS sheets that comply with industry standards and regulations. These sheets have enhanced fire resistance and can be used in applications where fire safety is a concern.

Q: What are the size and thickness options available for ABS sheets?

At Polyreflex, we offer a wide range of size and thickness options for ABS sheets. The standard sheet size is typically 4 feet by 8 feet (1220mm x 2440mm), but we can also provide custom sizes based on your project needs. Thickness options range from 1mm to 20mm or more, allowing for flexibility in various applications.

Q: Can ABS sheets be painted or coated?

Yes, ABS sheets can be painted or coated to achieve specific colors or desired finishes. Prior to painting or coating, it is important to clean the surface thoroughly and use compatible paints or coatings suitable for ABS materials. Our team can provide guidance on the appropriate paint or coating options for your specific requirements.

Q: Can ABS sheets be recycled?

ABS sheets are recyclable. They can be melted down and reprocessed into new ABS materials or other plastic products. Recycling ABS sheets helps reduce waste and supports sustainable practices. If you have specific recycling requirements or initiatives, our team can guide you on recycling options and best practices.

Q: Are ABS sheets suitable for food contact applications?

ABS sheets are not recommended for direct food contact applications. While ABS is generally considered safe and non-toxic, it is not specifically approved for food-grade use. If you require materials suitable for food contact applications, our team can assist you in exploring alternative options such as food-grade plastics or coatings.

Q: Why choose Polyreflex as your ABS sheets supplier?

Polyreflex stands out as a premier ABS sheets supplier, and here's why you should choose us:

Trusted Manufacturing - With years of experience in the industry, Polyreflex has established a strong reputation as a reliable and trusted ABS sheets manufacturer. We prioritize quality control and adhere to stringent production standards to ensure consistent, high-quality products.

Extensive Product Range - Our wide range of ABS sheets offers versatility for various applications. Whether you need standard sizes, custom dimensions, or specialized properties like flame resistance or UV stability, Polyreflex can fulfill your requirements.

Customization Options - We understand that every project has unique demands. At Polyreflex, we offer extensive customization services, including CNC cutting, laser engraving, vacuum forming, and printing. Our expert team can bring your vision to life and provide tailored solutions for your specific needs.

Superior Customer Service - Your satisfaction is our top priority. Our dedicated customer service team is here to assist you throughout the entire process, from product selection to after-sales support. We value open communication, prompt responses, and building long-term relationships with our clients.

Competitive Pricing - Polyreflex offers competitive pricing without compromising on quality. We strive to provide cost-effective solutions that meet your budgetary requirements, ensuring that you get the best value for your investment.

Sustainable Practices - We are committed to sustainability and eco-friendly manufacturing practices. By choosing Polyreflex, you support a supplier that prioritizes environmental responsibility and works towards minimizing our ecological footprint.

Made in China - Polyreflex is proud to be a Chinese manufacturer. We combine advanced technology, skilled craftsmanship, and efficient production processes to deliver ABS sheets of the highest standards. Choosing a local supplier like Polyreflex offers benefits such as shorter lead times, easier communication, and support for the local economy.

We hope this expanded FAQ section has addressed more of your questions about ABS sheets. As a leading manufacturer and provider of ABS solutions, Polyreflex is committed to delivering high-quality products, customization services, and expert guidance. Contact us today to discuss your specific requirements and discover how our ABS sheets can meet your project needs.

🔥 Take Action Now! 🔥

Contact us today to request a quote and claim your FREE sample! Let's bring your ideas to life with our exceptional Plastic ABS Sheets!

📞 Mobile/WhatsApp/Wechat: +8613828266785

📧 Email: sale@polyreflex.com

We look forward to partnering with you on your next venture!

- Discover Endless Possibilities with Polyreflex ABS Sheets

- Reach Out Now!