Your Trusted ABS Sheets Manufacturer in China: Polyreflex

- Share

- publisher

- Polyreflex

- Issue Time

- Sep 12,2023

Summary

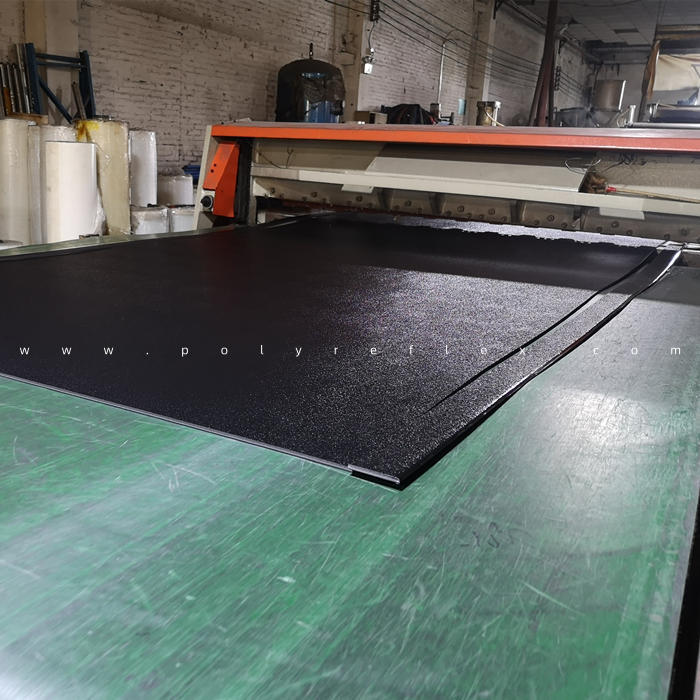

Polyreflex - Your trusted ABS sheets manufacturer, specializing in custom, high-quality thermoplastic sheets. Explore our versatile ABS sheets for various applications. ISO 9001 certified quality assurance.

Welcome to Polyreflex, where innovation meets excellence in the world of thermoplastic sheets. Established in 2006, Polyreflex has been at the forefront of the plastic sheet industry, specializing in a diverse range of high-quality thermoplastic sheets, including ABS sheets, TPO sheets, HDPE sheets, UHMWPE sheets, and PP sheets. With over a decade of dedicated experience, we have evolved into a leading manufacturer in China, renowned for our commitment to precision engineering and product quality.

In this article, we will delve into the fascinating world of ABS sheets, their manufacturing process, and the reasons why Polyreflex is your ultimate choice as an ABS sheets manufacturer. We will unveil the customization options we offer to cater to your unique requirements and showcase real-world applications that demonstrate the adaptability of our products. Furthermore, we will shed light on our unwavering commitment to quality assurance, as reflected in our compliance with the ISO 9001:2015 quality management system.

Join us on this journey through the realm of ABS sheets, and discover how Polyreflex sets the standard for excellence in thermoplastic sheet manufacturing.

What Are ABS Sheets?

ABS, or Acrylonitrile Butadiene Styrene, sheets are a versatile class of thermoplastic material known for their exceptional properties and wide-ranging applications. These sheets are composed of a blend of three key monomers: acrylonitrile, butadiene, and styrene. This unique combination results in a material that strikes a harmonious balance between strength, rigidity, and versatility.

Key Properties of ABS Sheets

Manufacturing Process of ABS Sheets

I. The Journey from Raw Materials to Finished ABS Sheets

The manufacturing of ABS sheets is a meticulous process that transforms raw materials into versatile thermoplastic sheets. Here's an overview of the key steps involved:

1. Raw Material Selection

The process begins with the careful selection of high-quality raw materials, including acrylonitrile, butadiene, and styrene monomers. These materials are sourced for their purity and consistency.

2. Monomer Polymerization

The selected monomers undergo polymerization through a process called emulsion polymerization. This step involves combining the monomers with initiators and surfactants to create a polymer.

3. Sheet Extrusion

The polymer is then processed through sheet extrusion equipment. This equipment melts the polymer and shapes it into flat sheets of varying thicknesses. Temperature and pressure control are critical to achieve the desired sheet properties.

4. Cooling and Sizing

The freshly extruded ABS sheets are rapidly cooled to solidify them. They are then precisely sized to meet the specified dimensions.

5. Surface Treatment

Surface treatment techniques, such as corona treatment, may be applied to enhance the adhesion properties of the ABS sheets.

6. Quality Testing

Throughout the manufacturing process, rigorous quality testing is conducted to ensure that the sheets meet the required standards for properties like thickness, strength, and color consistency.

II. Polyreflex's Commitment to Quality Assurance

At Polyreflex, quality is at the heart of our manufacturing process. We take several measures to maintain the highest standards:

- Raw Material Sourcing: We source raw materials from trusted suppliers, ensuring they meet our stringent quality requirements.

- Precision Manufacturing: Our state-of-the-art manufacturing facilities are equipped with advanced machinery and operated by skilled professionals to guarantee precision in every sheet produced.

- Quality Control Checks: Our quality control team conducts thorough checks at every stage of production, from extrusion to final sizing, to identify and rectify any deviations from specifications.

- ISO 9001:2015 Certification: Polyreflex proudly adheres to the ISO 9001:2015 quality management system, further demonstrating our commitment to quality.

III. Incorporating Advanced Techniques and Technologies

To stay at the forefront of ABS sheet manufacturing, Polyreflex continually explores and integrates advanced techniques and technologies. This includes innovations in extrusion processes, material blending, and surface treatment methods. These advancements enable us to offer ABS sheets with enhanced performance characteristics, catering to evolving industry needs.

Applications of ABS Sheets

ABS sheets, known for their exceptional versatility and durability, have found their way into an impressive array of real-world applications. At Polyreflex, we take pride in seeing our ABS sheets making a difference across industries. Here are some noteworthy examples:

Automotive Innovations

ABS sheets have revolutionized the automotive industry. They are extensively used in interior components such as dashboard panels, door trims, and consoles. Their ability to withstand harsh environmental conditions while maintaining an appealing aesthetic has made them a staple in car design.

Electronics Enclosures

ABS sheets are the go-to choice for electronic enclosures and housings. Their electrical insulating properties, coupled with impact resistance, ensure the safety and longevity of sensitive electronic components.

Impact-Resistant Safety Gear

ABS sheets are a vital component in the production of impact-resistant safety gear such as helmets and protective shields. Their ability to absorb impact without shattering makes them a trusted material for enhancing safety.

Durable Consumer Goods

From stylish luggage with tough exteriors to robust kitchen appliances, ABS sheets elevate the durability and visual appeal of various consumer products. They bring an element of reliability and longevity to everyday items.

Architectural Design

ABS sheets are employed in architectural applications, enhancing both interior and exterior aesthetics. They are used for decorative wall panels, signage, and even artistic installations.

Customized Solutions

Our clients have harnessed the power of customization to realize their unique visions. From specially designed retail displays to intricate prototypes, ABS sheets can be tailored to meet the specific demands of creative projects.

Why Choose Polyreflex as Your ABS Sheets Manufacturer

Ensuring Excellence through Rigorous Quality Assurance

At Polyreflex, our commitment to quality is unwavering, and it's ingrained in every step of our ABS sheet manufacturing process. Here's an insight into how we ensure product excellence:

- 1. Stringent Quality Control Checks: Our quality control begins with the selection of raw materials and extends to every stage of production. Each ABS sheet undergoes comprehensive testing to meet or exceed industry standards for properties such as thickness, strength, and color consistency.

- 2. State-of-the-Art Facilities: Our advanced manufacturing facilities are equipped with cutting-edge machinery and operated by skilled professionals. This synergy of technology and expertise ensures precision in every sheet we produce.

- 3. Adherence to Industry Standards: We adhere to globally recognized industry standards and best practices in ABS sheet manufacturing. This commitment guarantees that our products consistently meet the highest benchmarks for quality and performance.

- 4. Customization Control: Even in customized orders, we maintain strict control over the quality of ABS sheets. Tailored products are subject to the same rigorous quality control checks as our standard offerings.

- 5. Quality Feedback Loop: We actively seek feedback from our clients to continuously improve our products and processes. This iterative approach drives innovation and ensures that we remain at the forefront of quality and performance.

ISO 9001:2015 Certification

We're proud to announce that Polyreflex adheres to the ISO 9001:2015 quality management system. This internationally recognized certification underscores our commitment to quality, efficiency, and continuous improvement. It signifies that our manufacturing processes and quality control procedures align with the highest standards, giving you confidence in the quality of our ABS sheets.

Our adherence to ISO 9001:2015 is not just a certification; it's a commitment to excellence that translates into every ABS sheet we produce. With Polyreflex, you can expect nothing less than the best.

Customization Options

Exploring Your Customization Possibilities

At Polyreflex, we understand that one size doesn't fit all. That's why we offer a wide array of customization options for ABS sheets, allowing you to tailor your sheets to your exact specifications. Here's a glimpse of the customization possibilities:

- 1. Sheet Thickness: Choose from a range of thickness options to match your project's requirements. Whether you need thin, lightweight sheets or thick, robust ones, we've got you covered.

- 2. Color Selection: ABS sheets are available in a spectrum of colors. Select the color that aligns with your design preferences or branding needs.

- 3. Surface Textures: Customize the surface finish of your ABS sheets. Options include smooth, matte, or textured finishes to achieve the desired look and feel.

- 4. Cut-to-Size: Specify your preferred dimensions, and we'll cut the ABS sheets to precisely fit your application. This minimizes waste and simplifies installation.

- 5. Printing and Branding: If you require logos, labels, or other branding elements on your ABS sheets, we offer printing services to ensure your sheets arrive ready for use.

Tailoring ABS Sheets to Your Unique Needs

Your projects are unique, and we're here to accommodate those distinct requirements. Here's how you can customize ABS sheets to meet your specific needs:

1. Consultation

Our team of experts is available to discuss your project's specifications. We'll work closely with you to understand your goals and advise on the best customization options.

2. Prototyping

If you're unsure about the ideal customization for your project, we can provide prototype samples to help you visualize the end result.

3. Quality Assurance

Rest assured that our commitment to quality extends to customized orders. Your tailored ABS sheets will undergo the same rigorous quality control checks as our standard products.

4. Timely Delivery

We understand that time is often of the essence. We strive to deliver your customized ABS sheets promptly, ensuring that your project stays on schedule.

5. Flexibility

Whether you need a small quantity for a unique application or a large order for mass production, we can accommodate your volume requirements.

6. Technical Support

Our technical team is available to answer any questions and provide guidance throughout the customization process.

🔥 Take Action Now! 🔥

Contact us today to request a quote and claim your FREE sample! Let's bring your ideas to life with our exceptional Plastic ABS Sheets!

📞 Mobile/WhatsApp/Wechat: +8613828266785

📧 Email: sale@polyreflex.com

We look forward to partnering with you on your next venture!

- Discover Endless Possibilities with Polyreflex ABS Sheets

- Reach Out Now!