Manufacturing Process of HDPE Sheets: Polyreflex's Commitment to Quality and Innovation

- Share

- publisher

- Polyreflex

- Issue Time

- Oct 27,2023

Summary

Discover high-quality HDPE sheets by Polyreflex, a leading HDPE sheet manufacturer. Our durable, customized solutions cater to various industries, ensuring top-quality high-density polyethylene sheets.

HDPE (High-Density Polyethylene) sheets, also known as polyethylene sheets, plastic sheets, or PE sheets, are versatile materials used in various industries for their excellent durability, chemical resistance, and flexibility. At Polyreflex, we take immense pride in being a leading HDPE sheet manufacturer based in China. In this article, we will delve into the manufacturing process and the cutting-edge techniques that set Polyreflex apart.

Introduction to HDPE Sheets

HDPE sheets are a type of plastic sheet material known for their outstanding properties. They are lightweight, durable, and offer exceptional chemical resistance, making them suitable for a wide range of applications. HDPE sheets are used in industries like construction, agriculture, packaging, automotive, and more. They are highly preferred for their flexibility, impact resistance, and ability to withstand harsh environmental conditions.

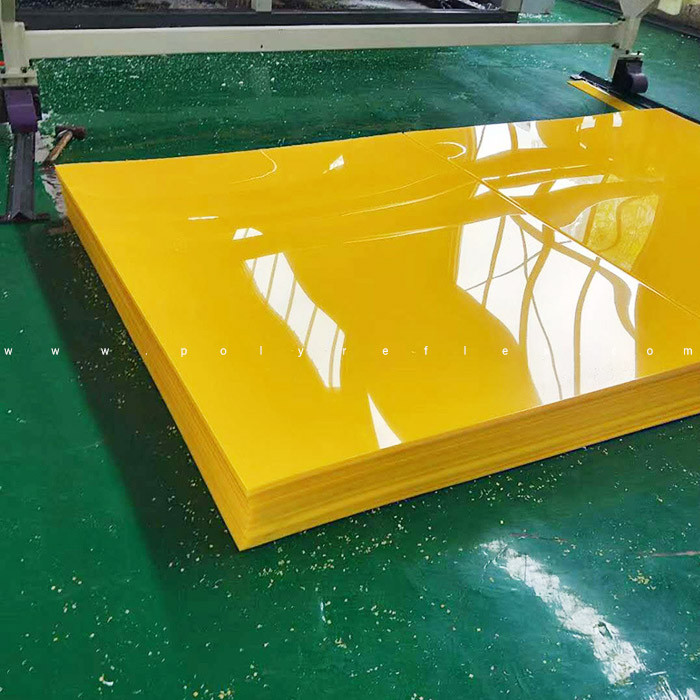

Yellow HDPE Sheet

Double-colored HDPE Sheet

Anti-slip HDPE Sheet for Temporary Road

The Manufacturing Process

1. Resin Extrusion

The manufacturing of HDPE sheets starts with the extrusion of high-density polyethylene resin. This resin is melted and forced through a die, resulting in a continuous sheet. Polyreflex uses top-quality HDPE resins, ensuring our sheets meet international standards for performance and safety.

2. Sheet Cooling

3. Sheet Cutting and Shaping

The cooled HDPE sheet is then cut and shaped according to specific requirements. Whether it's large rolls, flat sheets, or custom shapes, Polyreflex can accommodate various customer needs. Our state-of-the-art cutting machinery ensures precision and consistency.

4. Quality Control

Polyreflex takes quality control seriously. We implement stringent measures throughout the manufacturing process. Each batch of HDPE sheets undergoes rigorous testing for thickness, surface finish, mechanical properties, and other quality parameters. Our commitment to quality has earned us a reputation for delivering reliable and consistent products.

5. Customization

We understand that different industries have unique requirements. Polyreflex offers customization services to tailor HDPE sheets to meet specific needs. Whether it's color, thickness, surface texture, or additives, we work closely with our clients to provide solutions that fit their applications.

HDPE Sheet Welding

HDPE Sheet Assembling

HDPE Sheet for Water Treatment Tank

Polyreflex's Commitment

At Polyreflex, we pride ourselves on being a leading HDPE sheet manufacturer and supplier in China. Our commitment to innovation and quality is unwavering. Here's what sets us apart:

Advanced Manufacturing Technology

We invest in cutting-edge technology to ensure our manufacturing processes are efficient, precise, and environmentally friendly.

Quality Assurance

Our quality control measures are second to none. We believe in delivering only the best products to our customers.

Customization

We understand that one size doesn't fit all. Our ability to offer tailored solutions sets us apart from the competition.

Environmental Responsibility

We are committed to sustainable manufacturing practices, minimizing waste, and ensuring responsible resource usage.

Global Reach

With robust production capacity and extensive export experience, Polyreflex ensures continuous, reliable, and on-time delivery to customers worldwide.

In conclusion, HDPE sheets, with their versatility and exceptional properties, are indispensable materials in various industries. As a reputable manufacturer, Polyreflex takes pride in its commitment to quality and innovation, ensuring that our HDPE sheets meet the highest industry standards. We are your trusted partner for all your HDPE sheet needs. For inquiries, custom orders, or more information, please feel free to contact us.

Polyreflex - Your Trusted HDPE Sheet Manufacturer and Supplier

🔥 Take Action Now! 🔥

Contact us today to request a quote and claim your FREE sample! Let's bring your ideas to life with our exceptional HDPE Sheets!

📞 Mobile/WhatsApp/Wechat: +8613828266785

📧 Email: sale@polyreflex.com

We look forward to partnering with you on your next venture!

- Discover Endless Possibilities with Polyreflex HDPE Sheets

- Reach Out Now!