Is HDPE Sheet a Durable and Crack-Resistant Plastic Material?

- Share

- publisher

- Polyreflex

- Issue Time

- Nov 13,2023

Summary

Explore Polyreflex's range of HDPE sheets – a leading manufacturer providing durable and impact-resistant plastic solutions. Our chemical-resistant HDPE panels offer versatile applications, backed by customizable options for your specific needs.

Welcome to the world of high-density polyethylene (HDPE) sheets, where durability and crack resistance redefine the standards of plastic materials. As a leading manufacturer and supplier based in China, Polyreflex takes pride in presenting this comprehensive guide to showcase the unparalleled qualities of HDPE sheets.

Understanding the Basics of HDPE

HDPE, also known as high-density polyethylene, boasts a molecular structure and polymerization process that contribute to its remarkable characteristics. At its core, HDPE is composed of long chains of ethylene monomers, which are interconnected to form a high-density, linear polymer. The key structural feature contributing to HDPE's exceptional properties is its high degree of crystallinity. In HDPE, the polymer chains are densely packed in a regular, repeating pattern, creating a structure that resembles a well-organized lattice.

The molecular structure of HDPE, characterized by its high density and crystalline arrangement, coupled with a controlled polymerization process, contributes to the material's exceptional strength, stiffness, and durability. The density and hardness of HDPE play pivotal roles in determining its performance across various applications.

Yellow HDPE Sheet

Double-colored HDPE Sheet

Anti-slip HDPE Sheet for Temporary Road

Exploring the Durability of HDPE Sheets

HDPE sheets, proudly manufactured by Polyreflex, exhibit remarkable durability owing to their innate resistance to chemical corrosion and superior performance in moisture-prone environments. Let's delve into the specifics of these key attributes that make HDPE a resilient and long-lasting material.

Chemical Resistance

One of the standout features of Polyreflex HDPE sheets is their exceptional resistance to chemical corrosion. The molecular structure of HDPE imparts a high degree of inertness, making it resistant to a wide range of chemicals, acids, and bases. This quality is invaluable in industrial settings where exposure to corrosive substances is a common challenge.

Applications in Aggressive Environments

Polyreflex HDPE sheets find extensive use in chemical processing plants, laboratories, and industrial facilities where exposure to aggressive chemicals is a constant. The material's resistance ensures that it maintains its structural integrity, preventing degradation and ensuring a longer service life.

Low Maintenance Requirements

The chemical resistance of HDPE translates into low maintenance requirements. Equipment and structures fabricated from HDPE sheets require minimal attention, reducing downtime and operational costs over the long term.

HDPE Sheets Engineering Plastics

HDPE Sheets Welding Container

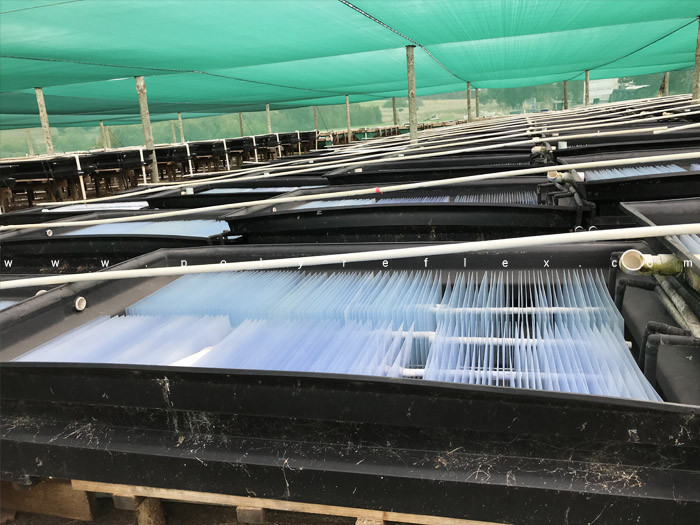

HDPE Sheets for Fish Farming

Moisture and Water Resistance

Polyreflex HDPE sheets also excel in their resistance to moisture and water absorption. This property makes them suitable for a myriad of applications where exposure to damp conditions is a consideration.

Indoor and Outdoor Versatility

Whether used indoors or outdoors, Polyreflex HDPE sheets remain unaffected by moisture. This versatility makes them ideal for applications ranging from storage containers and agricultural equipment to outdoor furniture and marine structures.

Protection Against Rot and Decay

In outdoor applications, where exposure to rain, humidity, and varying weather conditions is inevitable, HDPE's resistance to moisture prevents issues like rot and decay. This feature is particularly advantageous in construction and landscaping projects.

Unveiling the Crack Resistance of HDPE Sheets

Impact Resistance

One of the standout features of HDPE is its ability to withstand impacts. Polyreflex HDPE sheets find applications in environments where impacts are a common occurrence, such as manufacturing floors, transportation infrastructure, and construction sites. The material's resistance to cracking under impact ensures a prolonged service life and reduces the need for frequent replacements.

Flexibility under Strain

HDPE sheets demonstrate superior flexibility when subjected to bending and twisting forces. During installation, and in applications where structural movements are anticipated, HDPE sheets can flex without cracking, allowing for easier handling and adaptation to varying structural requirements. This flexibility ensures that the sheets conform to the contours of surfaces, reducing the risk of stress-induced cracks.

Temperature Extremes

Polyreflex HDPE sheets exhibit resilience to extreme temperatures, maintaining their structural integrity in both high and low temperature environments. In settings where exposure to high temperatures is prevalent, such as in industrial processes or outdoor installations, Polyreflex HDPE sheets remain stable without softening or deforming. Even in cold climates, where materials may become brittle, Polyreflex HDPE sheets retain their flexibility. This characteristic is crucial in applications like water infrastructure in cold regions.

Environmental Factors Shaping HDPE Performance

Understanding the environmental factors that shape HDPE performance is crucial for optimizing its application. Temperature effects play a significant role, as HDPE exhibits resistance to extremes but benefits from awareness of specific temperature requirements. Additionally, HDPE sheets are UV-resistant, making them well-suited for outdoor applications exposed to sunlight. This resistance to UV radiation not only prevents degradation but also ensures a lasting aesthetic appeal. In chemical-intensive environments, HDPE's resistance to corrosive substances proves invaluable, with Polyreflex HDPE sheets maintaining structural integrity even when exposed to aggressive chemicals. Overall, a comprehensive understanding of temperature, UV radiation, and chemical interactions is essential for maximizing the performance of HDPE in various applications.

The Importance of Proper Handling and Installation

Ensuring the optimal performance of HDPE involves prioritizing proper handling and installation practices, a focal point emphasized by Polyreflex. Following installation best practices is paramount, encompassing measures to prevent excessive stress, adherence to recommended guidelines, and the establishment of uniform support systems. Equally crucial are handling precautions, where meticulous care minimizes the risk of damage to HDPE sheets. Polyreflex underscores the importance of avoiding contact with sharp objects and emphasizes the significance of proper storage and transportation methods to preserve the material's integrity throughout its lifecycle. By incorporating these considerations into the process, the full potential of HDPE can be realized.

Polyreflex's HDPE sheets stand as a testament to durability, crack resistance, and adaptability. As a leading manufacturer and supplier from China, Polyreflex invites you to explore the limitless possibilities of HDPE and experience the difference that quality and expertise can make. For customized solutions and a reliable supply partner, choose Polyreflex – your trusted name in high-density polyethylene sheets.

- Discover Endless Possibilities with Polyreflex HDPE Sheets

- Reach Out Now!