What Are the Characteristics of HDPE Sheets?

- Share

- publisher

- Polyreflex

- Issue Time

- Nov 20,2023

Summary

Explore the exceptional characteristics of Polyreflex HDPE sheets – your go-to solution for chemical-resistant, impact-resistant, durability, lightweight, and weather-resistant plastic materials.

Welcome to the world of High-Density Polyethylene (HDPE) sheets, where Polyreflex, a leading Chinese manufacturer, brings innovation and reliability to your projects. In this comprehensive guide, we delve into the unique characteristics of HDPE sheets and showcase their versatile applications. As your go-to HDPE sheet supplier, Polyreflex combines quality manufacturing with customizable solutions to meet your specific needs.

Polyreflex: Your Trusted Partner in HDPE Solutions

1. Chemical Resistance

HDPE, or high-density polyethylene (PEHD), is renowned for its unparalleled chemical resistance, a feature that guarantees longevity and reliability in environments exposed to corrosive substances. This exceptional resistance extends across a spectrum of chemicals, ranging from acids to alkalis, making HDPE an ideal choice for the secure storage of corrosive chemicals in chemical storage tanks. This ensures a combination of safety and durability, making HDPE a preferred material for environments where resistance to a diverse array of chemicals is paramount.

2. High Impact Strength

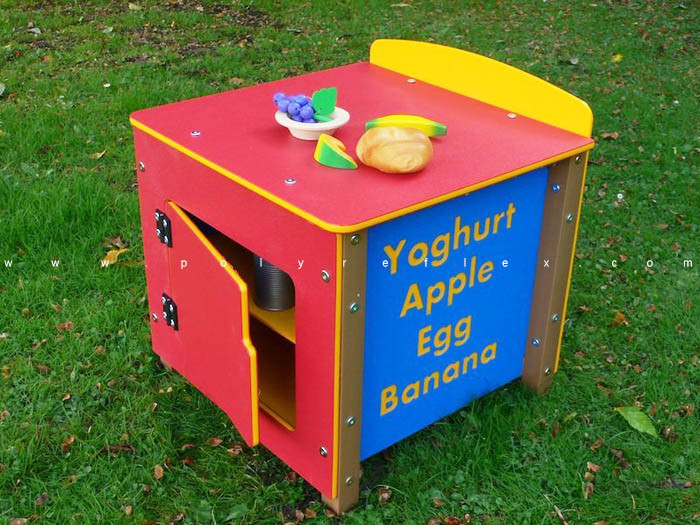

With its distinguished high impact strength, HDPE stands out in applications demanding durability and resilience against impact damage. Polyreflex's unwavering commitment to quality ensures that our HDPE sheets consistently deliver exceptional performance. HDPE sheets emerge as a dependable choice in scenarios such as playground equipment or automotive components, where the ability to withstand impact is crucial. Specifically designed for these situations, our HDPE sheets serve as protective barriers, guaranteeing both safety and longevity in environments where impact is a constant concern.

3. Lightweight Nature

The significance of lightweight materials holds paramount importance across various industries. Polyreflex's HDPE sheets, distinguished by their lightweight nature, play a pivotal role in facilitating easy handling, installation, and transportation, thereby contributing to an overall reduction in costs. Harnessing the advantages of HDPE's lightweight properties, it emerges as an excellent choice for packaging materials, enhancing logistical efficiency. Additionally, Our HDPE sheets find application in the construction of portable structures, offering a combination of durability and ease of transportation for versatile and convenient use.

4. Weather Resistance

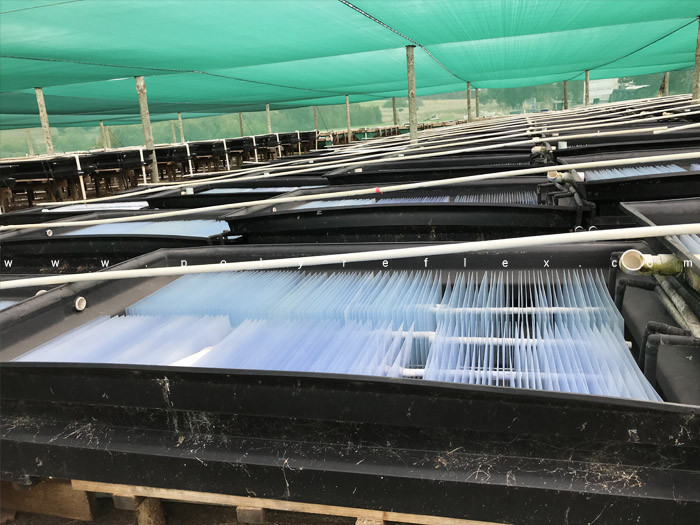

HDPE's remarkable resistance to weathering, UV radiation, and extreme temperatures positions it as a dependable choice for outdoor applications, guaranteeing both longevity and optimal performance in diverse environmental conditions. Our weather-resistant HDPE sheets find ideal use in crafting outdoor furniture, where their ability to withstand the elements ensures a combination of aesthetic appeal and long-lasting durability. Moreover, in sectors such as agriculture and construction, HDPE's inherent weather resistance proves advantageous, making it a versatile material for various outdoor applications.

5. Low Moisture Absorption

Understanding that moisture absorption can result in material degradation and dimensional instability, HDPE stands out with its low moisture absorption, ensuring the prolonged integrity of products even in moisture-sensitive environments. HDPE sheets are particularly well-suited for marine applications, where constant exposure to moisture is a concern. The low moisture absorption characteristics of HDPE make it a reliable choice for maintaining the structural stability and durability of materials in maritime environments.

6. Excellent Electrical Insulation

In industries where electrical conductivity is a critical consideration, HDPE emerges as an outstanding electrical insulator, offering a combination of safety and reliability. HDPE sheets play a vital role in electrical cable insulation, ensuring the secure transmission of electricity. Additionally, HDPE's exceptional electrical insulation properties make it a preferred choice for telecommunications conduits, where reliability in signal transmission is paramount.

7. Recyclability

UEmphasizing the significance of recyclability, Polyreflex, as a responsible manufacturer, places a strong focus on the recyclable nature of HDPE. This commitment contributes to sustainable and environmentally friendly practices. In alignment with eco-friendly principles, Polyreflex's commitment to recyclability finds practical application in the realm of packaging. By embracing recyclable HDPE, we actively contribute to the development of environmentally conscious packaging solutions for the benefit of consumers committed to sustainable practices.

8. Ease of Fabrication

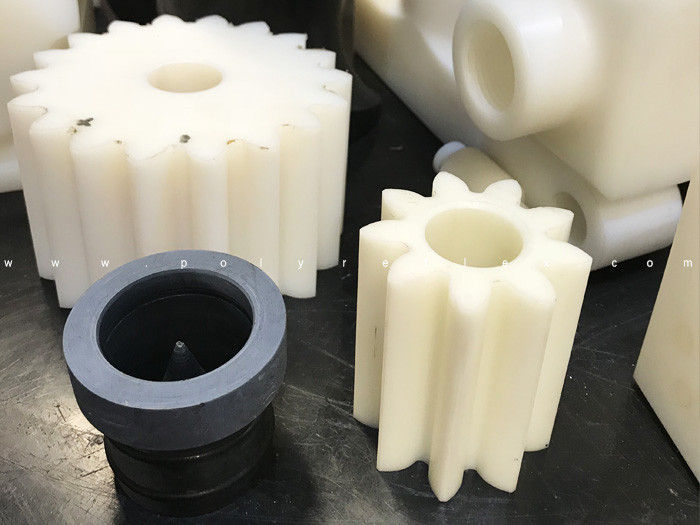

Polyreflex's HDPE sheets stand out for their ease of fabrication, accommodating various methods such as welding, machining, and thermoforming. This flexibility empowers designers and manufacturers with the freedom to create tailored solutions for diverse applications. The adaptability of HDPE's fabrication processes finds practical application in crafting custom containers, meeting specific requirements with precision. Moreover, in engineering applications, our HDPE sheets offer versatility, contributing to the development of robust and customized structures that align with unique project needs.

9. Abrasion Resistance

With its innate resistance to abrasion and wear, HDPE establishes itself as a reliable material in applications where durability is paramount. HDPE sheets play a pivotal role in crafting conveyor components, offering an ideal solution for environments with abrasive conditions. The abrasion resistance of HDPE makes it a suitable choice for liners in chutes and hoppers, providing longevity in settings prone to wear. This versatility positions HDPE as a dependable material for maintaining durability and performance in challenging industrial scenarios.

10. FDA Compliance

The significance of FDA compliance is paramount in applications where materials interact with food. Our FDA-compliant HDPE sheets find fitting applications in the manufacturing of food storage containers, ensuring the safety of consumable products through adherence to strict regulatory standards. Additionally, HDPE's compliance with food safety standards makes it an ideal material for cutting boards in commercial kitchens, where maintaining hygiene and safety in food preparation is of utmost importance. This commitment to regulatory compliance establishes HDPE as a trustworthy choice in environments where food contact safety is a primary concern.

Polyreflex takes pride in offering HDPE sheets with a myriad of exceptional characteristics. From chemical resistance to recyclability, our HDPE sheets find applications across diverse industries, showcasing the versatility and reliability of our products. As a leading Chinese manufacturer and supplier, Polyreflex not only delivers quality HDPE sheets but also offers customization to meet your unique requirements. Trust Polyreflex for innovative HDPE solutions that stand the test of time.

Visit Polyreflex for more information on our HDPE sheets and customized services. Your journey to reliable and tailored HDPE solutions starts here!

- Discover Endless Possibilities with Polyreflex HDPE Sheets

- Reach Out Now!