Is HDPE Environmentally Friendly?

- Share

- From

- https://www.polyreflex.com/

- publisher

- Polyreflex

- Issue Time

- Jan 22,2024

Summary

Explore the eco-friendly advantages of HDPE sheets with insights into sustainable manufacturing practices. Discover why Polyreflex is a leading HDPE manufacturer committed to providing environmentally responsible solutions. Learn more about the recyclability and green potential of HDPE for a sustainable future.

In a world increasingly conscious of environmental sustainability, the choice of materials plays a crucial role in shaping our collective impact. Plastics, while versatile and widely used, have come under scrutiny due to their long-lasting environmental implications. As we navigate through discussions on eco-friendly alternatives, one question often arises: Is High-Density Polyethylene (HDPE), particularly in the form of HDPE sheets, a sustainable and environmentally friendly choice?

Plastic pollution has become a global challenge, prompting individuals and industries alike to reassess their reliance on traditional materials. The quest for eco-conscious solutions has led many to explore alternatives that balance functionality with minimal environmental impact. In this exploration, HDPE emerges as a potential contender, known for its versatility and widespread applications. But does it truly hold the key to a more sustainable future? Polyreflex, as a manufacturer of HDPE sheet, we invite you to embark on this journey with us to uncover the environmental footprint of HDPE and determine whether it is a responsible choice in the material world.

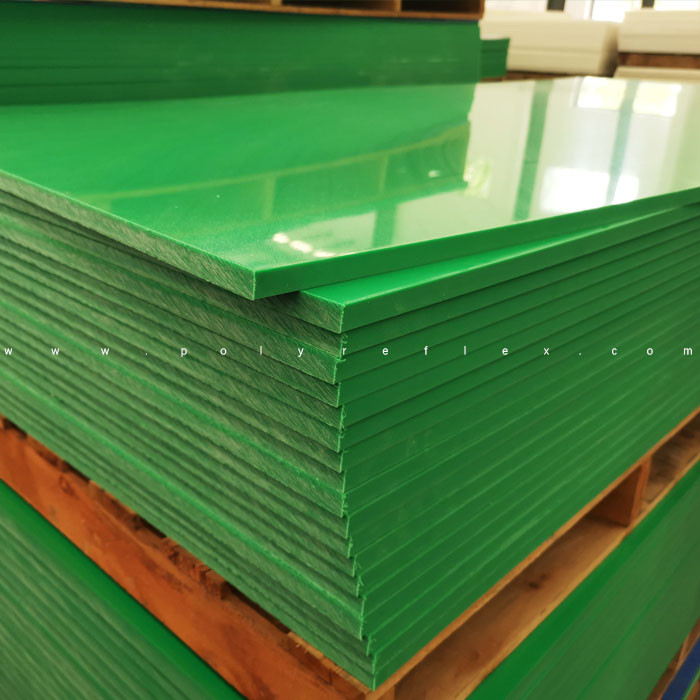

HDPE Sheets

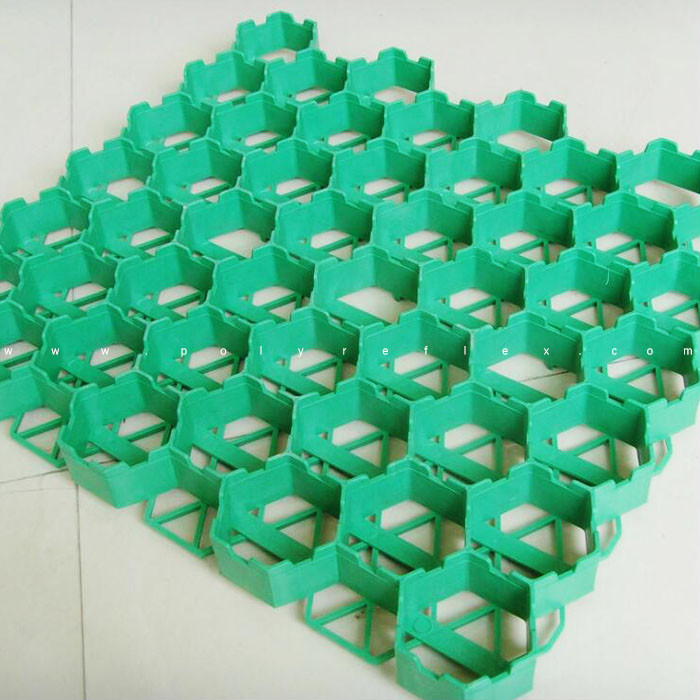

HDPE Grass Planting Grid

What is HDPE?

High-Density Polyethylene, commonly known as HDPE, stands out as a versatile and robust thermoplastic. It is synthesized from ethylene, a petroleum-derived compound, through a high-pressure process. What distinguishes HDPE is its molecular structure, characterized by a high density of polyethylene molecules. This structural design imparts unique mechanical properties, making HDPE a preferred material for an array of applications.

Common Applications of HDPE

HDPE's versatility is showcased through its extensive range of applications across diverse industries. In packaging, HDPE is widely employed for its strength and durability, ensuring the integrity of products during transportation. The construction sector embraces HDPE for geomembranes, pipes, and sheets, benefiting from its resilience and resistance to corrosion. Agricultural advancements leverage HDPE in greenhouse coverings and liners for irrigation systems, capitalizing on its impermeability and chemical resistance.

Beyond these sectors, HDPE plays a pivotal role in aquaculture infrastructure, providing a durable and corrosion-resistant material for fish tanks and floating cages. Its impact resistance and non-toxic nature also position HDPE sheets prominently in playground equipment, contributing to child safety.

Popularity Across Industries

The popularity of HDPE sheets is underlined by their prevalence in numerous industries. Their favorable attributes, including durability, flexibility, and chemical resistance, make them a top choice for manufacturers seeking reliable and sustainable materials. Whether in industrial manufacturing, construction, agriculture, or aquaculture, HDPE sheets have become synonymous with innovation and efficiency.

HDPE Plastic Pallets

HDPE Ground Protection Mats

Aquaculture HDPE Ponds

Environmental Attributes of HDPE

Recyclability and Plastic Waste Reduction:

One of the key environmental attributes that sets HDPE apart is its high level of recyclability. HDPE is widely recognized and accepted in recycling streams, making it a valuable contributor to efforts in reducing plastic waste. When properly recycled, HDPE can be transformed into a variety of products, extending its useful life and diverting significant amounts of plastic from landfills and the environment. The recyclability of HDPE aligns with the growing global emphasis on circular economies and sustainable material practices.Life Cycle Assessment (LCA) of HDPE:

Examining the life cycle of HDPE provides insights into its overall environmental impact. From raw material extraction to production, usage, and eventual disposal, HDPE boasts a comparatively low environmental footprint when contrasted with alternative materials. The production process of HDPE is energy-efficient, requiring less energy compared to the manufacturing of some other plastics. Furthermore, the durability and longevity of HDPE contribute to its positive life cycle assessment, as the need for replacement or disposal is minimized.Comparative Environmental Benefits:

Comparing HDPE to alternative materials, such as traditional plastics with shorter life spans or materials that require more energy-intensive production processes, emphasizes its environmental benefits. HDPE's resilience and durability translate to longer product lifetimes, reducing the frequency of replacements and, consequently, the overall environmental impact. This extended lifespan aligns with sustainability goals and positions HDPE as a responsible choice for those seeking environmentally friendly materials.Energy Efficiency and Production

Energy Efficiency in HDPE Production:

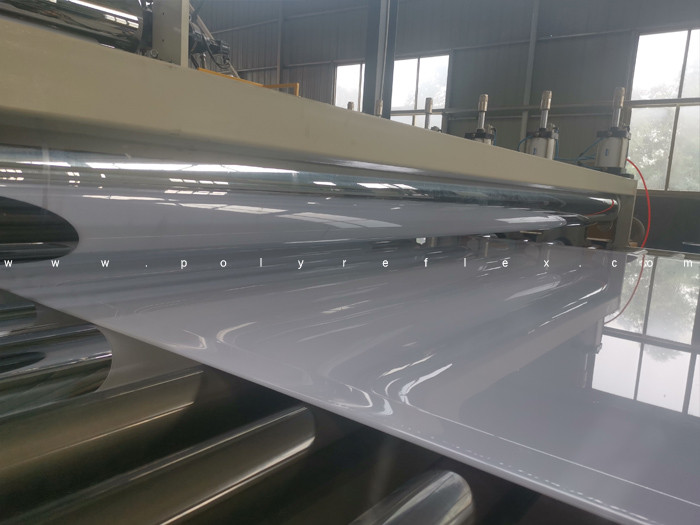

The production process of HDPE demonstrates a notable commitment to energy efficiency, aligning with environmental sustainability goals. The manufacture of HDPE involves a high-pressure polymerization process, where ethylene molecules are tightly packed to form the high-density polyethylene structure. This process stands out for its efficiency in converting raw materials into the final product, minimizing energy waste and resource consumption.The catalytic process employed in HDPE production is known for its energy-efficient nature, contributing to a reduced carbon footprint compared to some other plastic manufacturing methods. The streamlined processes not only optimize energy usage but also enhance the overall efficiency of HDPE production, making it a favorable choice for those seeking eco-friendly materials.

Comparative Energy Consumption:

When assessing the environmental impact of plastics, the energy consumed during production is a critical factor. HDPE, with its energy-efficient manufacturing process, exhibits favorable characteristics compared to certain other plastics. The lower energy requirements in the production of HDPE contribute to reduced greenhouse gas emissions and resource usage.Comparative studies often highlight HDPE as a more sustainable option in terms of energy consumption when pitted against materials with energy-intensive manufacturing processes. This distinction positions HDPE as an environmentally responsible choice, particularly for those conscious of the broader ecological implications of material production.

In essence, the energy efficiency embedded in HDPE production not only reflects a commitment to sustainable practices but also enhances its standing as a material with a comparatively lower environmental impact, contributing to the broader efforts towards a more eco-conscious industrial landscape.

End-of-Life Options

Recycling Advantages

One of the notable environmental advantages of HDPE is its excellent recyclability. When HDPE sheets reach the end of their useful life, they can be collected, processed, and recycled into new products. The recycling process for HDPE is well-established, contributing to a closed-loop system that minimizes the reliance on virgin materials. This not only conserves resources but also reduces the energy demand associated with the production of new materials.

Repurposing and Reuse

Beyond traditional recycling, HDPE sheets offer opportunities for repurposing and reuse. Their inherent durability and resistance to degradation make them suitable for extended use in various applications. Repurposing HDPE sheets into new products or extending their lifespan through creative applications contributes to a more sustainable approach to material utilization.

Circular Economy Potential

The end-of-life options for HDPE sheets align seamlessly with the concept of a circular economy. By incorporating recycling and repurposing into the material's life cycle, HDPE contributes to the creation of a closed-loop system where waste is minimized, and resources are continuously reused. This circular approach reduces environmental impacts, conserves raw materials, and lessens the burden on waste management systems.

Innovations in Circular Economy Practices

In recent years, there has been a growing emphasis on circular economy practices, and HDPE stands as a material that naturally fits into this paradigm. Innovations in recycling technologies and collection systems further enhance the feasibility of establishing a circular economy with HDPE. This creates a positive feedback loop where recycled HDPE becomes a valuable resource for manufacturing new products, fostering a sustainable and regenerative approach to material usage.

Polyreflex's Commitment to Sustainable Practices

Polyreflex, as a leading manufacturer of HDPE sheets, shares a steadfast commitment to sustainable practices and environmental responsibility. Our production processes prioritize energy efficiency and waste reduction, aligning with industry best practices for eco-friendly manufacturing. By integrating cutting-edge technologies and sustainable sourcing, Polyreflex aims to minimize its environmental impact while delivering high-quality HDPE products to our customers. By choosing Polyreflex's HDPE sheets, customers not only benefit from a versatile and durable material but also contribute to a more sustainable and circular economy.

As we stand at the crossroads of material choices, the call to action is clear: let informed decisions pave the way for a greener, more sustainable environment, where HDPE stands as a beacon of responsible and eco-friendly innovation.

HDPE Sheets Manufacturing

HDPE Sheets in Stock

- Discover Endless Possibilities with Polyreflex HDPE Sheets

- Reach Out Now!