The Manufacturing Process of PP Honeycomb Panels: What You Need to Know

- Share

- From

- https://www.polyreflex.com/

- publisher

- Polyreflex

- Issue Time

- Sep 20,2024

Summary

Learn about the detailed manufacturing process of PP Honeycomb Panels at Polyreflex. From raw materials to final production steps, discover how these lightweight, durable panels are crafted to meet the highest industry standards.

Polyreflex is a trusted manufacturer of high-quality PP Honeycomb Panels, known for their strength, durability, and lightweight properties. These panels are widely used across industries such as construction, packaging, and automotive due to their exceptional load-bearing capacity and impact resistance. Understanding the manufacturing process of PP Honeycomb Panels is crucial for ensuring you choose the right product for your needs. A well-crafted panel not only guarantees long-lasting performance but also maximizes cost-efficiency, making it a reliable solution for various demanding applications.

Understanding PP Honeycomb Panels

PP Honeycomb Panels are engineered marvels designed for both strength and versatility. These panels consist of a unique honeycomb core structure sandwiched between two layers of polypropylene (PP) sheets. The honeycomb core, shaped like a hexagonal lattice, creates a lightweight yet highly durable material. This design effectively distributes weight and absorbs impact, making the panels strong enough to withstand various stresses while maintaining a low overall weight.

Key Properties:

1. Lightweight: The honeycomb structure significantly reduces the panel' s weight compared to solid materials, making them easier to handle and install.

2. Durable: PP Honeycomb Panels are resistant to impact, chemicals, and moisture, ensuring longevity even in harsh environments.

3. Strong: The honeycomb core enhances the panel's load-bearing capacity, providing excellent structural support without adding excessive bulk.

Industries and Applications:

PP Honeycomb Panels are incredibly versatile and find applications across numerous industries:

By leveraging their unique properties, PP Honeycomb Panels provide effective solutions for a variety of demanding applications, ensuring both performance and efficiency.

Raw Materials Used

The manufacturing of PP Honeycomb Panels begins with the selection of high-quality raw materials, which are crucial to achieving the panels' superior performance and durability.

Polypropylene (PP): The primary material used in PP Honeycomb Panels is polypropylene, a thermoplastic polymer known for its strength, flexibility, and resistance to impact and chemicals. Polypropylene comes in various grades, and for honeycomb panels, high-density PP is typically used to enhance the panel’s structural integrity and longevity. The polypropylene sheets that form the outer layers of the panel provide a strong protective barrier, while the honeycomb core, also made from PP, offers lightweight strength and effective load distribution.

Other Materials: In addition to polypropylene, various additives and bonding agents are used to optimize the properties of the panels. These can include:

Importance of Material Quality:

The quality of raw materials plays a pivotal role in the final product' s performance. High-quality polypropylene ensures that the panels are robust, with excellent impact resistance and durability. The use of superior additives and bonding agents further enhances the panels' resistance to environmental factors and mechanical stress. By maintaining strict quality control over the materials used, Polyreflex ensures that each PP Honeycomb Panel meets the highest standards of performance and reliability, providing customers with a dependable product for various applications.

The Step-by-Step Manufacturing Process

Creating PP Honeycomb Panels involves a meticulous process designed to ensure the panels are both strong and lightweight. Here' s a detailed look at each step in the manufacturing process:

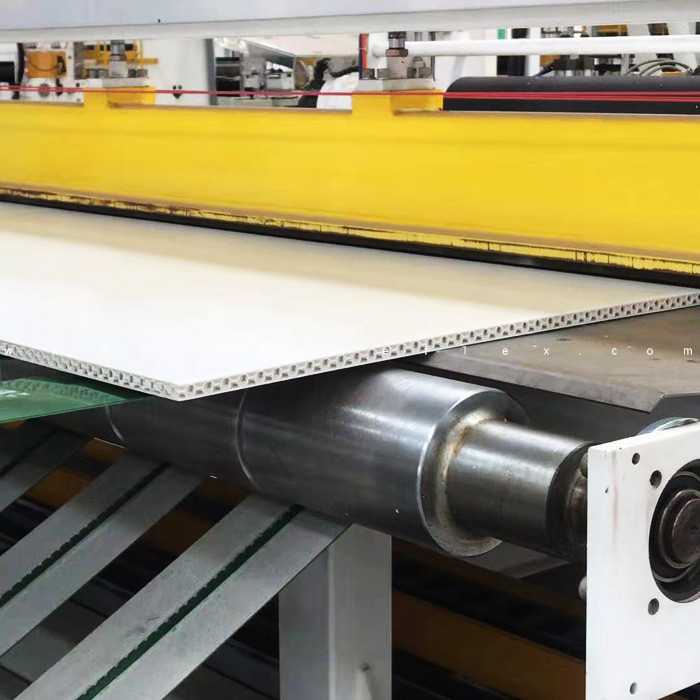

1. Extrusion of the Core

The process begins with the extrusion of the honeycomb core. Polypropylene (PP) resin is melted and fed through an extrusion die, which shapes the material into a continuous honeycomb structure. This core, with its hexagonal lattice design, is crucial for the panel' s strength and lightness. The extrusion process ensures the honeycomb cells are uniform in size and density, contributing to the panel's overall durability and performance.

2. Thermal Bonding

Once the honeycomb core is extruded, it undergoes a thermal bonding process. The core is subjected to heat and pressure to bond it firmly to the outer polypropylene sheets. This thermal bonding not only secures the core to the sheets but also enhances the structural integrity of the panel. The bonding process ensures that the core remains firmly in place, providing the panel with its characteristic strength and stability.

3. Layering Process

After thermal bonding, the core is sandwiched between two layers of polypropylene sheets. These outer layers are typically pre-cut to the desired dimensions and are fused to the honeycomb core using heat and pressure. This layering process creates a strong, cohesive panel where the outer sheets act as a protective cover while the honeycomb core provides lightweight strength. The combination of these materials results in a panel that is both resilient and efficient in load-bearing applications.

4. Cutting and Shaping

With the basic panel structure complete, the next step involves precision cutting and shaping. Using advanced CNC (Computer Numerical Control) machinery, the panels are cut to specific sizes and shapes as required by the customer. This precision ensures that the panels meet exact specifications and can be seamlessly integrated into various applications. The CNC equipment allows for intricate designs and customizations, enhancing the panel's versatility.

5. Quality Control

Throughout the manufacturing process, rigorous quality control measures are implemented. Each panel undergoes thorough inspections to ensure it meets the highest standards of quality and performance. Quality checks include assessing the panel' s dimensions, structural integrity, and bonding strength. Any deviations from the standards are promptly addressed to maintain consistency and reliability in every panel produced.

This comprehensive manufacturing process ensures that Polyreflex' s PP Honeycomb Panels are of exceptional quality, offering durability, strength, and versatility for a wide range of applications.

Environmental and Economic Advantages

PP Honeycomb Panels offer significant environmental and economic benefits, making them a smart choice for both sustainable practices and cost-effective solutions.

Eco-Friendly Nature: PP Honeycomb Panels are designed with environmental responsibility in mind. The primary material, polypropylene (PP), is fully recyclable, meaning that end-of-life panels can be processed and reused, reducing waste and environmental impact. The manufacturing process itself is energy-efficient, utilizing advanced techniques that minimize energy consumption and emissions. Additionally, the lightweight nature of the panels contributes to lower transportation costs and reduced carbon footprint, as less energy is required to transport these panels compared to heavier materials.

Cost-Effectiveness: From an economic perspective, PP Honeycomb Panels offer substantial cost savings. Their lightweight properties not only simplify handling and installation but also reduce shipping and handling costs. The durability of these panels means they require less frequent replacement, providing long-term savings over alternative materials that may wear out more quickly. Moreover, the energy-efficient manufacturing process translates to lower production costs, which can be passed on to customers in the form of competitive pricing. Investing in PP Honeycomb Panels means benefiting from a combination of economic efficiency and environmental sustainability, making them a practical choice for various applications.

Overall, PP Honeycomb Panels are a cost-effective and environmentally friendly option, aligning with both ecological and economic goals while providing high performance and durability.

Customization Options

PP Honeycomb Panels are highly versatile and can be tailored to meet specific requirements across various applications. Here' s a look at the customization options available to enhance the functionality and aesthetics of these panels:

1. Size and Thickness

One of the key customization options is the size and thickness of the panels. PP Honeycomb Panels can be manufactured in a wide range of dimensions to fit different spaces and applications. Whether you need large panels for expansive surfaces or smaller panels for more intricate designs, the ability to adjust size and thickness ensures that the panels meet precise specifications. The thickness of the panels can also be customized to achieve desired strength and load-bearing capabilities.

2. Color

The color of PP Honeycomb Panels can be customized to match aesthetic requirements or brand guidelines. Panels can be produced in various colors, from standard shades to custom hues, allowing them to seamlessly integrate into different environments. This customization enhances the visual appeal of the panels and ensures they align with the design requirements of any project.

3. Surface Finishes

Different surface finishes can be applied to the panels to achieve specific textures and appearances. Options may include matte, gloss, or textured finishes, depending on the desired look and functionality. Surface finishes can impact both the aesthetic quality and practical attributes, such as slip resistance or scratch resistance.

4. Additional Features

Additional features can be incorporated into the panels based on user needs. This may include features such as fire resistance, enhanced UV protection, or antimicrobial properties. Customization can also extend to integrating pre-cut holes, slots, or custom shapes to accommodate specific design elements or functional requirements.

5. Edge Treatments

Custom edge treatments can be applied to enhance the durability and appearance of the panels. Options might include edge banding or reinforcement to improve the panel's resistance to damage and wear, ensuring longevity and maintaining a polished look.

By leveraging these customization options, Polyreflex enables clients to create PP Honeycomb Panels that are tailored precisely to their needs. This flexibility ensures that each panel not only performs optimally but also complements the unique requirements of various applications, from construction and automotive to packaging and beyond.

Understanding the manufacturing process of PP Honeycomb Panels is crucial for selecting the right material for your needs. This process ensures that the panels offer exceptional strength, durability, and versatility, making them suitable for a wide range of applications. By knowing the details of how these panels are made, you can make informed decisions and choose the best options for your projects.

For tailored solutions and further information, don' t hesitate to reach out to Polyreflex. Our team is ready to assist you with expert guidance and provide customized quotes to meet your specific requirements. Explore the possibilities with PP Honeycomb Panels and discover how they can enhance your next project.