The Manufacturing Process of PP Bubble Board: What You Need to Know

- Share

- From

- https://www.polyreflex.com/

- publisher

- Polyreflex

- Issue Time

- Sep 9,2025

Summary

Discover how Polyreflex manufactures high-quality PP Bubble Boards using advanced co-extrusion technology. Learn about the step-by-step production process, material structure, and quality control that make our polypropylene bubble sheets lightweight, durable, and eco-friendly.

PP Bubble Board, also known as polypropylene bubble sheet, is a lightweight yet durable thermoplastic material that has gained wide popularity across various industries — from packaging and automotive to construction and display. Its distinctive internal bubble structure gives it excellent strength, rigidity, and cushioning properties, while keeping it remarkably light in weight.

At Polyreflex, we have over 18 years of manufacturing experience specializing in polypropylene sheet materials. In this article, we'll take you behind the scenes to explore the complete manufacturing process of PP Bubble Board, so you can better understand how this innovative material is made and what makes it so reliable.

What Is PP Bubble Board Made Of?

The main raw material used in PP Bubble Board is polypropylene (PP) resin — a versatile thermoplastic polymer known for its toughness, chemical resistance, and recyclability. To achieve specific performance characteristics, the PP resin is blended with several functional additives, such as:

Polyreflex uses 100% virgin polypropylene resin, ensuring that every sheet maintains stable physical properties, superior appearance, and consistent quality.

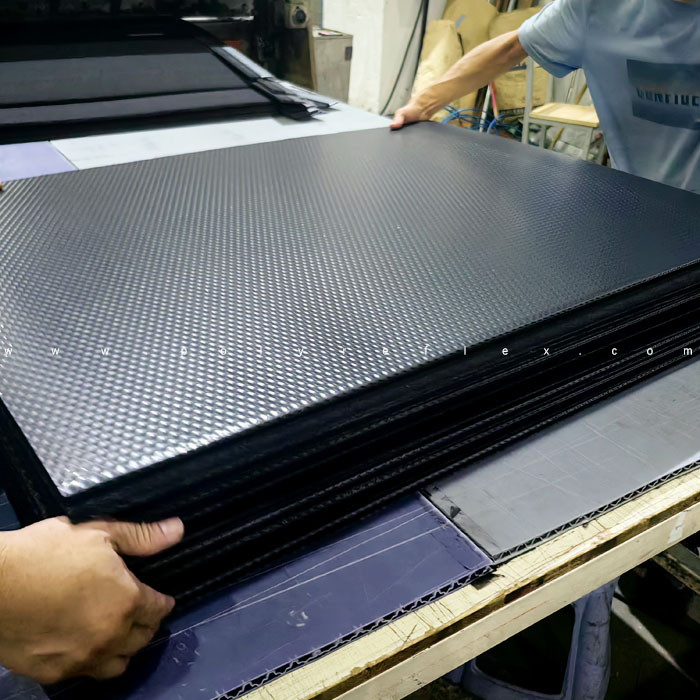

The Structure of PP Bubble Board

Unlike solid sheets, PP Bubble Board is built with a three-layer co-extruded structure:

The middle layer contains numerous sealed air bubbles arranged in a hexagonal or circular pattern. These air-filled bubbles provide cushioning and rigidity, similar to the concept of a honeycomb. This structure allows PP Bubble Board to achieve a perfect balance between strength, stiffness, and light weight.

Step-by-Step Manufacturing Process

1. Raw Material Preparation

The process begins with the selection of high-purity PP resin pellets. These pellets are mixed with additives and color masterbatch according to the required formula. The mixture is then dried and prepared for extrusion.

2. Co-extrusion

The dried material is fed into a co-extrusion line equipped with multiple extruders. One extruder produces the top and bottom skin layers, Another extruder forms the bubble core layer. The materials are melted and combined in a multi-layer extrusion die, ensuring excellent adhesion between the layers. This co-extrusion process is the key to creating a uniform and durable PP Bubble Board with consistent thickness and density.

3. Bubble Formation

As the molten material passes through the specialized die, air pressure and temperature are precisely controlled to form sealed air pockets — the “bubbles.” The size and distribution of these bubbles directly affect the board's strength and weight. Polyreflex uses precision-designed forming molds to ensure a stable, evenly distributed bubble structure. This step gives the PP Bubble Board its unique internal architecture, combining flexibility with mechanical rigidity.

4. Cooling and Calibration

After the bubble structure is formed, the sheet passes through a cooling and calibration system that shapes it into the desired thickness and flattens the surface. Cooling rollers control the sheet temperature and prevent deformation. The calibration table ensures consistent thickness tolerance and smooth surface finish. This step is critical to achieving dimensional stability and surface uniformity in the final product.

5. Surface Treatment (Corona or Lamination)

Depending on the intended application, PP Bubble Board can undergo surface treatment to enhance its performance:

At Polyreflex, our surface-treated PP Bubble Boards offer excellent printability and versatility, making them suitable for both industrial and commercial use.

6. Cutting and Finishing

Once the board cools and solidifies, it is trimmed and cut into standard or custom sizes.

Polyreflex offers full customization, including:

Each batch is labeled and packed for shipment or further processing, such as die-cutting, bending, or welding.

Quality Control and Testing

Every PP Bubble Board produced by Polyreflex undergoes strict quality control at multiple stages of production. Key tests include:

We maintain an ISO 9001-certified quality management system, ensuring consistent product performance that meets international standards.

Customization Options

To meet diverse industry demands, Polyreflex offers custom PP Bubble Boards with specialized functions:

Our experienced engineering team can adjust the formulation, surface texture, and mechanical strength according to your specific requirements.

Advantages of PP Bubble Board Manufactured by Polyreflex

Choosing Polyreflex means choosing reliability and innovation.

Our PP Bubble Boards stand out because of:

Whether you need material for packaging, automotive lining, or reusable containers, Polyreflex delivers dependable performance every time.

From raw material preparation to precise bubble formation, every step in the manufacturing process of PP Bubble Board contributes to its superior mechanical strength, lightweight design, and versatility.

With advanced technology and years of expertise, Polyreflex ensures that each PP Bubble Board meets the highest quality standards.

Contact Polyreflex today to learn more about our PP Bubble Board solutions or to request a quote for your next project.