How Durable Is PP Bubble Board in Harsh Automotive Environments?

- Share

- From

- https://www.polyreflex.com/

- publisher

- Polyreflex

- Issue Time

- Oct 11,2025

Summary

Discover how PP Bubble Board excels in harsh automotive environments, offering durability, impact resistance, chemical resistance, and lightweight performance for interior panels, protective packaging, and structural components.

In the automotive industry, materials are constantly subjected to harsh environments, including extreme temperatures, vibrations, moisture, and chemical exposure. Selecting the right material for interior panels, protective packaging, or structural components is critical to ensure vehicle safety, longevity, and performance. Among the many options available, PP Bubble Board has emerged as a lightweight, durable, and cost-effective solution. But how well does it actually perform under harsh automotive conditions? This article explores the durability, applications, and advantages of PP Bubble Board in the automotive sector.

What Is PP Bubble Board?

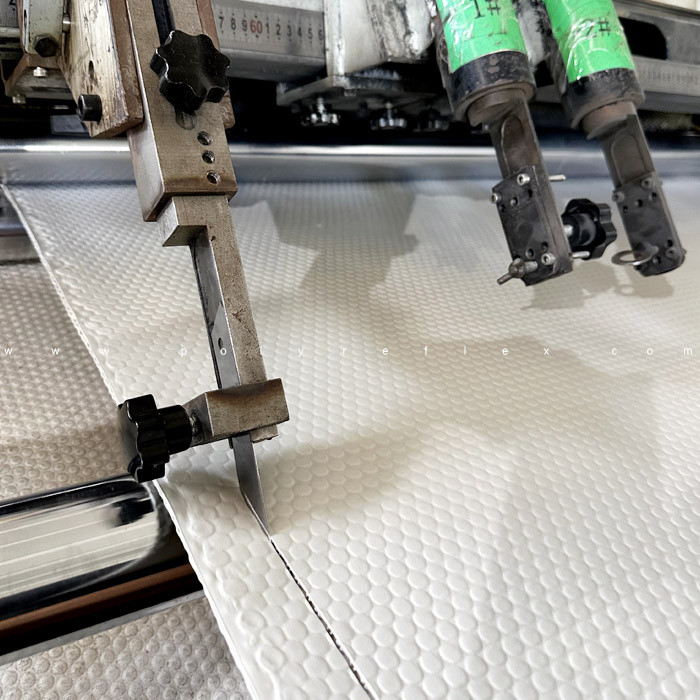

PP Bubble Board, also known as polypropylene bubble sheet, is a lightweight, hollow-structured plastic panel made from high-quality polypropylene. Its signature feature is the air-filled bubble core sandwiched between solid PP layers, which provides excellent impact resistance and shock absorption.

Key characteristics of PP Bubble Board include:

Unlike traditional ABS or PVC sheets, PP Bubble Board offers a unique combination of strength, flexibility, and low weight—making it ideal for automotive applications.

Harsh Automotive Environments Defined

Automotive components face numerous challenges that test the durability of materials:

1. Temperature Extremes: Vehicles operate in environments ranging from sub-zero winters to scorching summers. Materials must remain stable without warping or cracking.

2. Vibrations and Impact: Constant exposure to road vibrations, bumps, and accidental impacts can weaken or damage inferior panels.

3. Chemical and Oil Exposure: Engine oil, cleaning chemicals, and other fluids can corrode or degrade certain plastics.

4. Moisture and Humidity: From rainwater to interior condensation, moisture can cause swelling or mold growth in unsuitable materials.

PP Bubble Board is designed to withstand all these conditions while maintaining structural integrity.

Key Performance of PP Bubble Board in Automotive Applications

1. Impact Resistance & Shock Absorption

The hollow bubble core structure absorbs shocks and distributes stress evenly. This makes it ideal for panels and protective packaging, reducing the risk of dents or cracks.

2. Chemical and Oil Resistance

PP Bubble Board exhibits strong resistance to common automotive chemicals, including oils, coolants, and cleaning agents, ensuring longevity even in challenging environments.

3. Temperature Tolerance

PP Bubble Board remains stable under a wide temperature range, typically from -40°C to +80°C, without warping, cracking, or losing strength.

4. Lightweight Advantage

Reducing vehicle weight is crucial for fuel efficiency and performance. PP Bubble Board is significantly lighter than metal panels, helping manufacturers achieve weight reduction goals.

5. Moisture and Corrosion Resistance

Unlike wood-based panels or cardboard alternatives, PP Bubble Board does not absorb water or develop mold, ensuring consistent performance in wet or humid conditions.

Real-World Automotive Applications

PP Bubble Board is widely used across the automotive industry for both interior and functional applications:

Its combination of strength, flexibility, and light weight makes it an ideal choice for multiple automotive use cases.

Case Studies & Testing Results

Independent tests and real-world usage confirm PP Bubble Board's performance:

Additionally, leading automotive brands have successfully integrated PP Bubble Board in interior panels and packaging solutions, reporting reduced weight and improved durability.

Comparison With Other Materials

| Material | Weight | Impact Resistance | Chemical Resistance | Cost |

PP Bubble Board | Light | Excellent | Excellent | Moderate |

| ABS Sheet | Medium | Good | Moderate | Higher |

| PVC Sheet | Medium | Moderate | Good | Moderate |

| Metal Panel | Heavy | Excellent | Excellent | High |

PP Bubble Board stands out for lightweight performance combined with durability and chemical resistance, offering a superior cost-to-benefit ratio for automotive applications.

PP Bubble Board proves to be a highly durable, versatile, and lightweight material suitable for harsh automotive environments. Its excellent impact resistance, temperature tolerance, chemical resistance, and moisture protection make it a preferred choice for interior panels, structural supports, and protective packaging. For automotive manufacturers and suppliers looking to enhance product durability while reducing weight, PP Bubble Board is an ideal solution.

Polyreflex, with 18 years of manufacturing experience, offers customized PP Bubble Board solutions tailored to the unique requirements of automotive applications. Contact us today to explore how our products can improve durability and efficiency in your automotive projects.