Flame Resistant Plastic Board Polypropylene PP Bubble Sheet for Automotive

- Model

- PR-BU

Item specifics

- Brand

- Polyreflex Polypropylene PP bubble board

- Provided Service

- Die-cutting, CNC Engraveing,Sealing, Bending, Welding, Printing,Attaching Spunbond…

- Custom Work

- Color, Width, Length, Size, Weight, Packing, Processing

- Certificate

- RoSH, REACH, V0-V2 @UL94, No Lead, No Formaldehyde Content.

- Main Application

- floor protection, side/back/roof panel for auto...

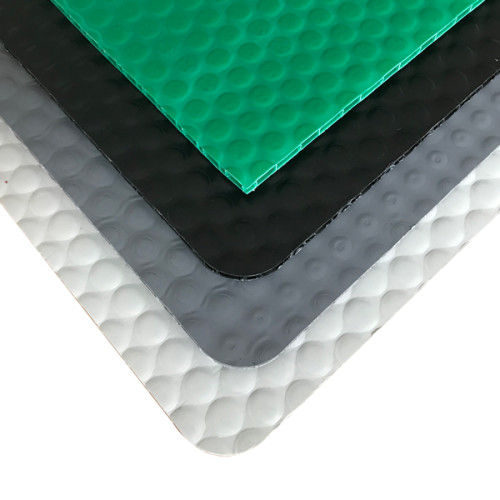

- Main Colors

- black, dark grey, light grey, etc.

- Update Time

- 2019-12-30

Review

Description

DETAIL INFORMATIONSPolyreflex Polypropylene (PP) bubble board

Polypropylene (PP) bubble board

High impact

Flame retardant

Low VOC emission

Polyreflex Polypropylene (PP) Bubble Board

Environment friendly & Flame retardant

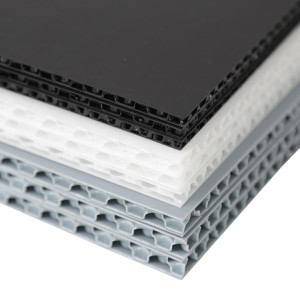

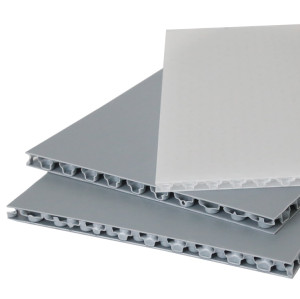

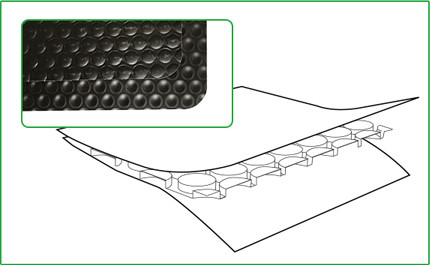

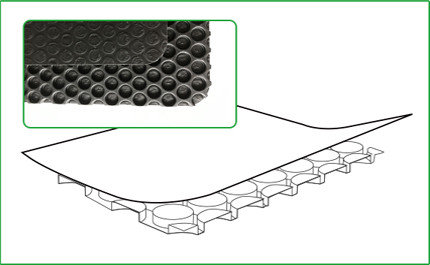

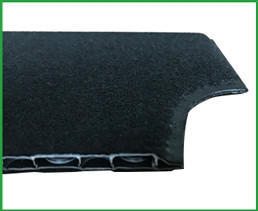

Polyreflex Polypropylene bubble board exhibits a unique sandwich structure

with a honeycomb structure inside and one/two flat surfaces with bubble

finish. It is Environment friendly, Flame retardant and durable.

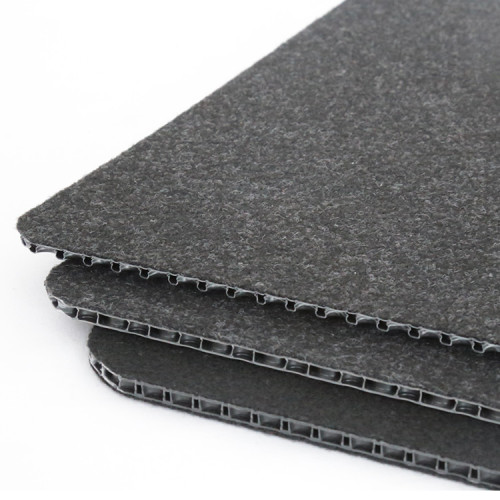

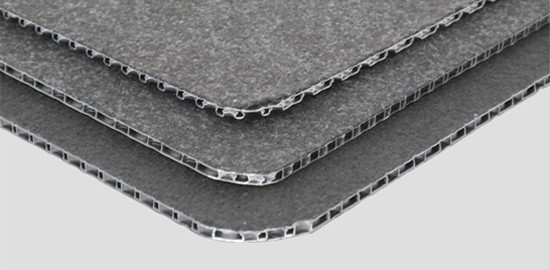

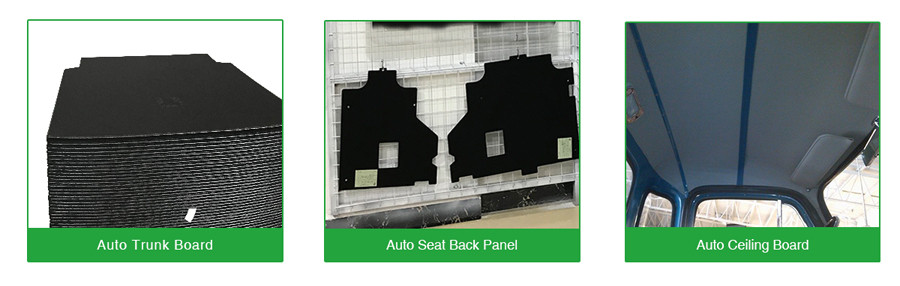

PP bubble board can be laminated with non-woven fabric. It is used as

spare wheel covers in the automobile luggage compartment, to achieve

the isolation function of spare tire and luggage compartment. It is also

used as luggage liner panel, seat back panel, side and roof panel of

mini-van, SUV, caravan etc.

It plays the role of body decoration, noise insulation, noise

reduction, load bearing and other.

with a honeycomb structure inside and one/two flat surfaces with bubble

finish. It is Environment friendly, Flame retardant and durable.

PP bubble board can be laminated with non-woven fabric. It is used as

spare wheel covers in the automobile luggage compartment, to achieve

the isolation function of spare tire and luggage compartment. It is also

used as luggage liner panel, seat back panel, side and roof panel of

mini-van, SUV, caravan etc.

It plays the role of body decoration, noise insulation, noise

reduction, load bearing and other.

Features

- Light Weight – Approx. 50% Lighter Than Wood

- Numerous Options for Surface Finishing

- Dimension Stability and Waterproof

- Noise Insulation, Noise Reduction

- Excellent Compression Strength

- Corrosion and Rot Resistant

- Easy to Post Process

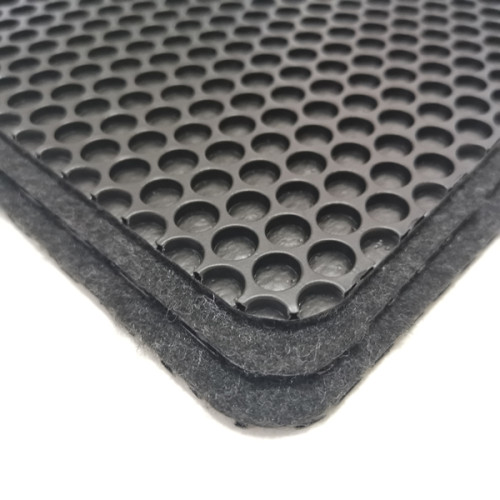

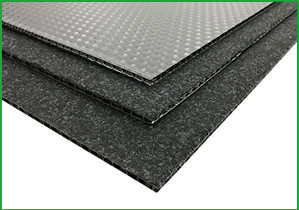

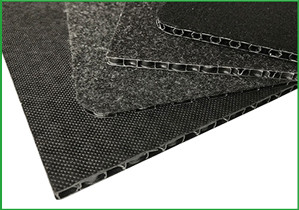

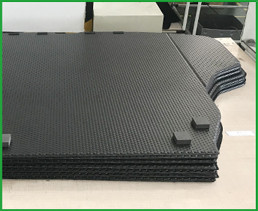

PP Bubble Board with / without Fabric

Surface with Different Fabric

Detailed Images

Quality is shown in detail

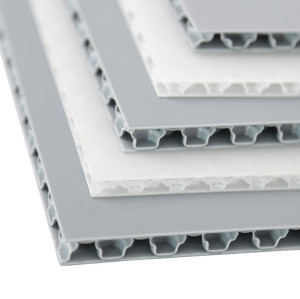

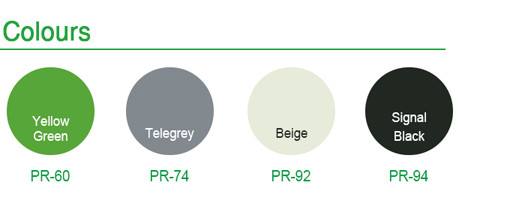

Color Options of PP Bubble Board without Fabric

Thickness Range from 3mm to 11mm

Three Layer: Surface + Honeycomb Core + Surface

Double Layer: Surface + Honeycomb Core

Product Available

| Items | Modle | ||

| PP bubble board | PP bubble board with non-woven fabric | ||

| Thickness: | 3-11mm | 3-12mm | |

| Width: | Max. Width 1.5M. 900-1300mm are popular. Other width can be customized. | ||

| Size: | 1000x2000mm, 1200x2400mm, 1220x2440mm are standard. Other size can be customized. | ||

| Colour: | Black, gray, beige are available. Other colors can be customized according to RAL / Pantone. | Board | Black, gray, beige are available. Other colors can be customized according to RAL / Pantone. |

| Fabirc | Black, light black. | ||

| Weight: | 750-3800gsm. | Board | 750-3500gsm |

| Fabirc | 80-300gsm | ||

| Surface: | bubble surface | Single or double side for fabric lamination is available. | |

Color

Number

RAL

Yellow Green

PR-60

6018

Telegrey

PR-74

7046

Beige

PR-92

9002

Signal Black

PR-94

9004

Main Features

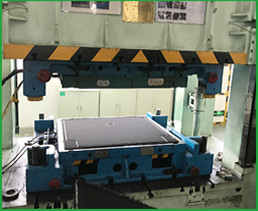

PROCESSING WAYSPolyreflex Polypropylene (PP) bubble board

Die-cutting

Creasing

Edge Sealing by Cloth

Edge Sealing by Cloth

Edge Sealing by Hot Melt

Pressing by Hot Mold

Polyreflex Polypropylene Bubble Boards Application Examples

Polyreflex Polypropylene(PP) Bubble Boards are excellent alternative to Plywood, MDF, Particleboard, Block Board etc.

For Auto Tire Cover

Durable/Low VOC emission/Flame resistance

For Auto Body Decoration

High Strength/High impact resistant/Easily DIY

For Protection

Scratching Resistant/Durable Service/High Impact Resistant to Protect