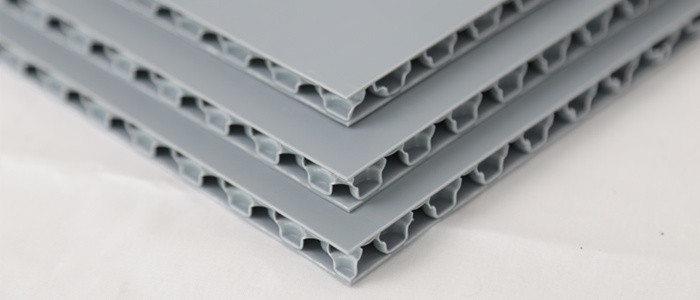

Polyreflex corrugated plastic boxes

are designed for durability, lightweight handling, and cost-effectiveness. Made from high-quality polypropylene, these boxes provide superior strength compared to traditional cardboard, making them ideal for long-term use and reducing packaging waste.

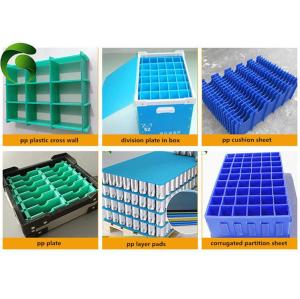

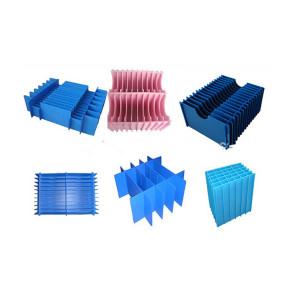

These boxes are perfect for protecting and transporting fragile, valuable, or moisture-sensitive items such as electronics, cosmetics, fruits, and beverages. Their strong, impact-resistant construction ensures your products are kept safe during storage and transit.

Ideal for industries like e-commerce, logistics, and agriculture, these versatile boxes are well-suited for shipping goods to distributors, retailers, and consumers. They can also be customized in size, color, and print to meet specific branding and functional needs.