Polyreflex Pallet Sleeve Container

is developed to be durable, returnable and economical, provide a perfect solution for logistics and turnover systems to support, store, protect and transport unit loads of bulk goods or materials.

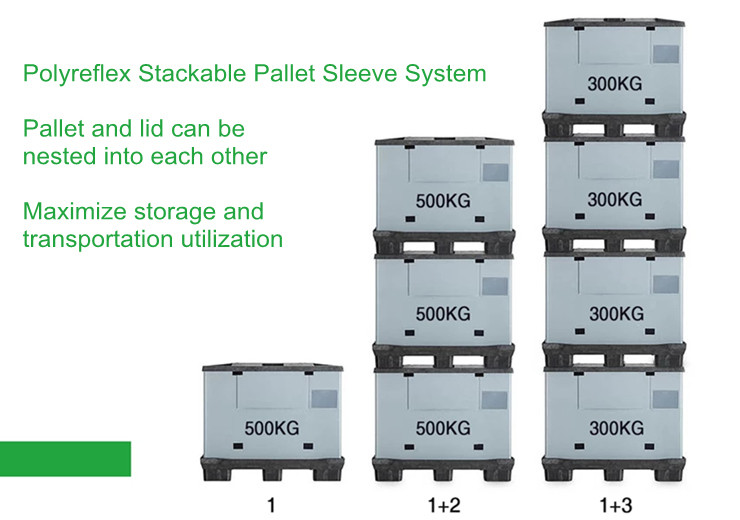

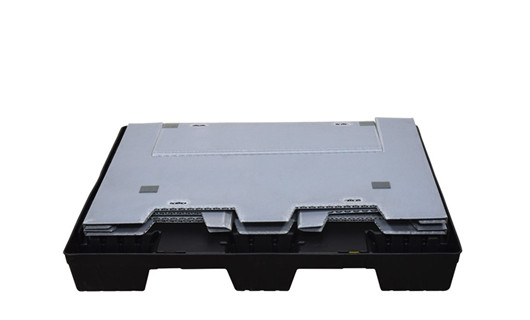

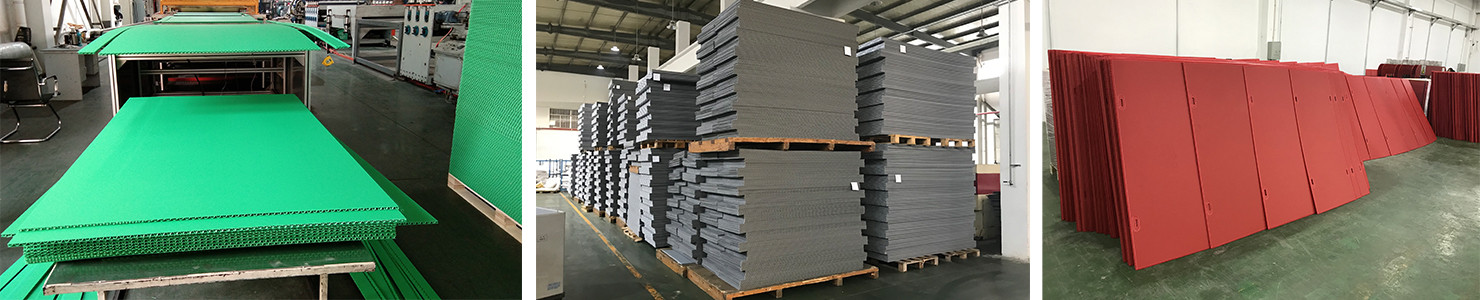

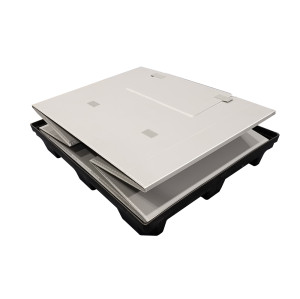

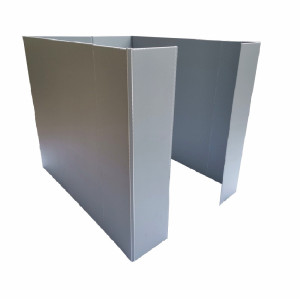

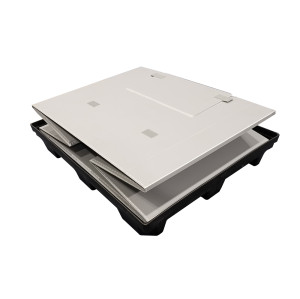

A sleeve pack is made up of a HDPE pallet base, collapsible polypropylene triple walls, and a top lid. The pallet base and top lid are nestable and thus the sleeve pack systems can be stably stacked to help optimize storage and transportation utilization.

Polyreflex pallet sleeve system adopts all-in-one design, when empty, sleeve packs are collapsed, the top lid, pallet base and sleeve are available as a set, providing an excellent empty container return rate, helping to reduce transportation costs and storage space.