What is the Difference Between ABS and PVC Sheet?

- Share

- From

- https://www.polyreflex.com/

- publisher

- Polyreflex

- Issue Time

- Apr 3,2024

Summary

Discover the critical distinctions between ABS and PVC sheets in our comprehensive comparison. Learn about the advantages, applications, and considerations when choosing between these thermoplastic materials. As a leading ABS sheet manufacturer, we provide insights to help you make informed decisions for your specific needs.

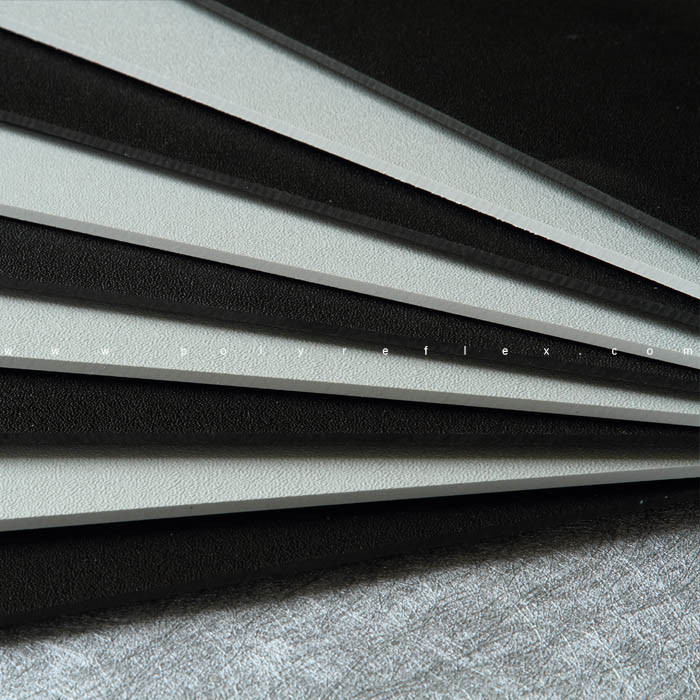

Welcome to Polyreflex, your trusted source for thermoplastic sheets. In this article, we'll explore a fundamental question in the realm of plastic materials: What is the difference between ABS (Acrylonitrile Butadiene Styrene) and PVC (Polyvinyl Chloride) sheets?

ABS and PVC sheets are both widely used thermoplastics with distinct properties and applications. ABS is known for its exceptional strength, impact resistance, and heat resistance, making it a popular choice for a variety of industries. On the other hand, PVC is valued for its versatility, low cost, and chemical resistance, making it ubiquitous in numerous applications.

Understanding the disparities between ABS and PVC sheets is crucial for making informed decisions in material selection. Whether you're involved in automotive manufacturing, electronics production, or consumer goods development, choosing the right material can significantly impact product performance, durability, and cost-effectiveness.

Composition and Properties

Composition of ABS Sheets

ABS sheets are composed of a blend of three main monomers: Acrylonitrile, Butadiene, and Styrene. These monomers are polymerized to form a thermoplastic material known for its balanced properties. During the manufacturing process, the three monomers are combined in specific proportions and then subjected to polymerization, resulting in the formation of the ABS resin. This resin is then extruded into sheets of various thicknesses, ready to be used in a wide range of applications.

Manufacturing Process of ABS Sheets

The manufacturing process of ABS sheets typically involves several stages. Initially, the raw materials, including the three monomers and additives such as stabilizers and pigments, are mixed together in precise proportions. The mixture is then heated and melted in an extruder, where it undergoes compounding to ensure uniform distribution of additives and consistent properties. Next, the molten ABS compound is extruded through a die to form continuous sheets, which are then cooled and solidified. Finally, the sheets are trimmed, cut to size, and packaged for distribution.

Properties of ABS Sheets

ABS sheets exhibit a unique combination of properties that make them suitable for a wide range of applications:

1. Strength: ABS sheets are known for their excellent strength, providing structural integrity and durability in various environments. They can withstand mechanical stress and impact without cracking or breaking, making them ideal for applications that require resilience and toughness.

2. Impact Resistance: One of the key advantages of ABS sheets is their high impact resistance. They can absorb energy from impacts and distribute it throughout the material, minimizing the risk of damage or deformation. This property makes ABS sheets suitable for applications where impact resistance is essential, such as automotive components and protective casings.

3. Heat Resistance: ABS sheets have good heat resistance, allowing them to maintain their structural integrity at elevated temperatures. They have a relatively high heat deflection temperature, meaning they can withstand moderate levels of heat without softening or deforming. This property makes ABS sheets suitable for applications where thermal stability is required, such as electrical enclosures and housing for electronic devices.

Comparison with PVC Sheets

When compared to PVC sheets, ABS sheets exhibit some distinct differences in composition and properties:

1. Composition: While both ABS and PVC sheets are thermoplastics, they are composed of different monomers. ABS sheets contain Acrylonitrile, Butadiene, and Styrene, whereas PVC sheets are composed of Polyvinyl Chloride. This difference in composition leads to variations in mechanical properties, chemical resistance, and processing characteristics.

2. Properties: ABS sheets generally have higher impact resistance and heat resistance compared to PVC sheets. They are more suitable for applications requiring toughness and durability, such as automotive parts, electronics housings, and consumer products. PVC sheets, on the other hand, excel in chemical resistance and cost-effectiveness, making them ideal for applications such as piping, signage, and packaging.

In summary, ABS sheets offer a unique combination of strength, impact resistance, and heat resistance, making them versatile materials for a wide range of applications. Understanding their composition and properties is essential for choosing the right material for specific requirements.

Applications

ABS sheets find extensive use across various industries due to their unique combination of properties. Let's explore some common applications and compare their suitability with PVC sheets:

1. Automotive Parts

ABS sheets are widely used in the automotive industry for interior and exterior components. They are favored for their impact resistance, durability, and ability to be molded into complex shapes. Common applications include dashboard panels, door trims, wheel covers, and exterior body parts. ABS sheets provide the strength and resilience required to withstand the rigors of daily use and environmental exposure.

2. Consumer Goods

ABS sheets are popular in the production of consumer goods due to their aesthetic appeal and versatility. They are used to manufacture a wide range of products, including appliances, luggage, toys, and household items. ABS sheets can be easily molded, painted, and finished to achieve desired aesthetics while maintaining structural integrity and durability.

3. Electronics

ABS sheets play a crucial role in the electronics industry, where they are used for housings, enclosures, and structural components. Their ability to withstand heat, impact, and environmental factors makes them ideal for protecting electronic devices and components. ABS sheets also provide excellent electrical insulation properties, ensuring the safety and reliability of electronic systems.

4. Specific Industries or Uses

ABS sheets find specialized applications in industries such as healthcare, signage, and furniture manufacturing. In the healthcare sector, ABS sheets are used for medical equipment housings and components due to their durability and ease of sterilization. In signage, ABS sheets are valued for their ability to withstand outdoor exposure and maintain vibrant colors over time. Additionally, ABS sheets are utilized in furniture manufacturing for their strength, versatility, and aesthetic appeal.

In summary, ABS sheets are versatile materials with diverse applications across multiple industries. While PVC sheets may be suitable for certain applications, ABS sheets offer superior impact resistance, durability, and dimensional stability, making them preferred choices for demanding applications in automotive, consumer goods, electronics, healthcare, signage, and furniture manufacturing industries.

Advantages and Disadvantages

Advantages of ABS Sheets

1. Durability: ABS sheets are renowned for their exceptional durability and toughness. They can withstand impacts, scratches, and abrasion, making them suitable for applications that require long-term performance and resilience.

2. Versatility: ABS sheets offer versatility in terms of processing and fabrication. They can be easily molded, machined, and thermoformed into various shapes and designs, allowing for customization to meet specific application requirements.

3. Chemical Resistance: ABS sheets exhibit good resistance to chemicals, oils, and solvents, enhancing their suitability for applications where exposure to harsh substances is a concern. This property ensures the longevity and integrity of ABS components in challenging environments.

4. Aesthetic Appeal: ABS sheets are available in a wide range of colors and finishes, enabling designers to achieve desired aesthetics and branding requirements. They can be painted, printed, or laminated to enhance visual appeal and promote brand identity.

Disadvantages of ABS Sheets

1. Limited Heat Resistance: One of the main disadvantages of ABS sheets is their limited heat resistance compared to other thermoplastics. They have a relatively low heat deflection temperature, which may restrict their use in applications exposed to high temperatures or thermal cycling.

2. Poor Weathering Resistance: ABS sheets may degrade over time when exposed to prolonged sunlight and outdoor conditions. UV radiation and weathering can cause discoloration, fading, and surface degradation, reducing the aesthetic appeal and mechanical properties of ABS components.

3. Potential for Warping: ABS sheets have a tendency to warp or deform under certain conditions, particularly when subjected to uneven heating or cooling during processing. Proper design and processing techniques are essential to minimize the risk of warping and ensure dimensional stability.

Vacuum formed products find widespread applications across various industries due to their versatility, cost-effectiveness, and ability to produce complex shapes with relative ease. Here's a detailed overview of the diverse industries that utilize vacuum formed products and specific examples of products made through vacuum forming:

Contrast with PVC Sheets

When comparing ABS sheets with PVC sheets, several differences in advantages and disadvantages can be observed:

In summary, while ABS sheets offer several advantages in terms of durability, versatility, and aesthetic appeal, they also have limitations such as limited heat resistance and weathering resistance. Understanding these advantages and disadvantages is essential for selecting the most suitable material for specific applications and ensuring optimal performance and durability.

In conclusion, ABS and PVC sheets each offer distinct advantages and applications. ABS sheets are prized for their durability and versatility, making them suitable for a wide range of industries including automotive, consumer goods, and electronics. PVC sheets excel in chemical resistance and cost-effectiveness, ideal for applications such as piping and signage.

When selecting between ABS and PVC sheets, it's crucial to consider specific requirements and environmental concerns. By weighing the advantages and disadvantages of each material and making informed decisions, you can ensure optimal performance and sustainability in your projects.

Explore Polyreflex's range of thermoplastic sheets to find the perfect solution for your needs. Let us be your trusted partner in material solutions.