What Is PP Bubble Board and What Are Its Advantages?

- Share

- From

- https://www.polyreflex.com/

- publisher

- Polyreflex

- Issue Time

- May 7,2025

Summary

Discover the advantages of PP Bubble Board and why it's an ideal lightweight, durable, and eco-friendly alternative to traditional materials like plywood and solid plastic sheet in automotive applications. Learn more from Polyreflex, a trusted Chinese manufacturer with 18 years of experience.

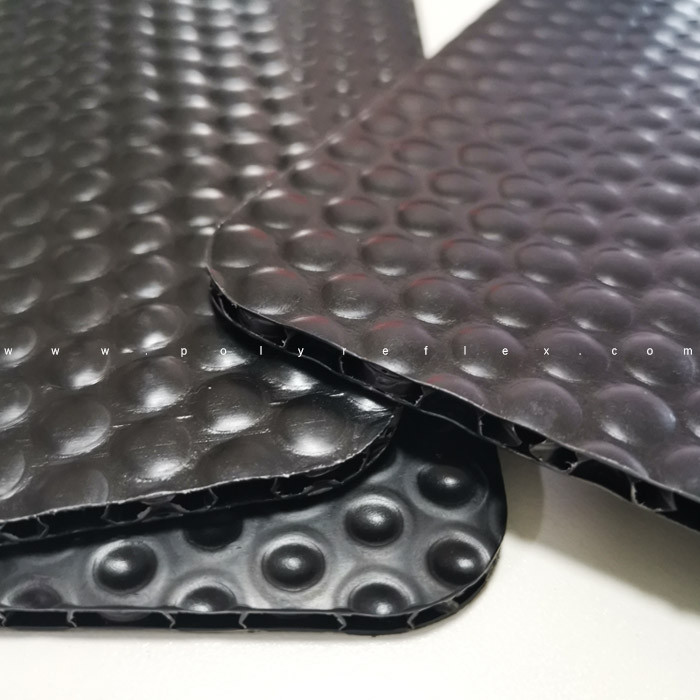

PP Bubble Board is an innovative lightweight plastic sheet made from polypropylene (PP), designed with a unique three-layer structure — two flat outer layers and a bubble-shaped core in the middle. This design gives the sheet a perfect balance of strength, durability, and light weight, making it a popular material in industries like automotive, packaging, logistics, and construction.

Polyreflex is a leading manufacturer of PP Bubble Board in China, with 18 years of experience in production and customization. We supply high-quality PP Bubble Boards in various thicknesses, weights, and colors to meet diverse application needs.

Structure of PP Bubble Board

PP Bubble Board is made through a co-extrusion process that forms:

This structure makes it lighter than solid plastic sheets while offering better impact resistance than corrugated or hollow-core sheets.

Key Advantages of PP Bubble Board

1. Lightweight yet Strong

The bubble core reduces the overall weight by up to 40% compared to solid PP sheets, without compromising on strength or stiffness.

2. Excellent Impact Resistance

The air-filled bubble structure absorbs shocks effectively, making it ideal for protective packaging and automotive interiors.

3. Waterproof and Chemical Resistant

PP material is naturally resistant to moisture, oil, and most chemicals — suitable for outdoor and harsh environments.

4. Eco-Friendly and Recyclable

Made from 100% polypropylene, PP Bubble Board is fully recyclable and free from harmful substances like heavy metals or halogens.

5. Thermoformable and Easy to Process

It can be easily cut, CNC-machined, welded, or thermoformed into various shapes and components.

6. Printable Surface

The flat surface allows for screen printing, digital printing, and lamination, making it suitable for signs and branding.

7. Customizable

Available in a wide range of thicknesses (2mm to 15mm), colors, surface textures, and additional treatments like corona or anti-UV.

What Traditional Materials Can PP Bubble Board Replace?

PP Bubble Board offers a smart alternative to several conventional materials, especially in applications that require a balance of lightweight, durability, and recyclability. Here are some of the most common materials that PP Bubble Board can effectively replace:

1. Plywood and MDF (Medium Density Fiberboard)

Used in trunk floors, door panels, and cargo liners, plywood and MDF are heavy and prone to moisture damage. PP Bubble Board offers a lighter, waterproof, and recyclable alternative with similar strength.

2. Corrugated Paperboard

Widely used in packaging, corrugated cardboard is not durable in humid conditions and is typically single-use. PP Bubble Board provides a reusable, moisture-resistant solution with higher impact strength.

3. Solid Polypropylene or Polyethylene Sheets

Although solid plastic sheets are strong, they are heavier and more expensive. PP Bubble Board achieves comparable rigidity with significantly less weight and material cost.

4. PVC Foam Board

Often used in signage and interior panels, PVC foam boards are heavier and less environmentally friendly. PP Bubble Board is halogen-free, more eco-conscious, and easier to recycle.

5. Aluminum Composite Panels (ACP) in Non-Structural Applications

In temporary partitions or interior auto components, ACP is often over-engineered. PP Bubble Board serves as a cost-effective, easier-to-process alternative that is also recyclable.

Applications of PP Bubble Board

Thanks to its combination of properties, PP Bubble Board is widely used in:

PP Bubble Board is a versatile, durable, and sustainable material that outperforms many traditional plastic and paper-based solutions. By replacing conventional materials like plywood, corrugated cardboard, and PVC foam board, PP Bubble Board enables industries to achieve better performance while reducing cost and environmental impact.

At Polyreflex, we are committed to delivering tailor-made PP Bubble Boards that meet the highest standards in quality and functionality. If you're looking for a lightweight, recyclable, and cost-effective material for your next project, PP Bubble Board is the smart choice.

Contact Polyreflex today for a free sample or quote.