Comparing PP Corrugated Sheets with Cardboard in Beverage Transportation

- Share

- From

- https://www.polyreflex.com/

- publisher

- Polyreflex

- Issue Time

- Aug 6,2025

Summary

Discover why PP corrugated sheets are a superior alternative to cardboard in beverage transportation. Learn about their waterproof, reusable, and durable features that enhance logistics, reduce waste, and lower long-term costs for the beverage industry.

In the beverage industry, packaging plays a critical role not only in protecting products during transportation but also in maintaining efficiency throughout the supply chain. For decades, cardboard has been the standard packaging material for beverage boxes, bottle dividers, and crate liners. However, as distribution conditions become more demanding—with increased moisture exposure, longer transit distances, and the growing need for reusable solutions—traditional cardboard often falls short.

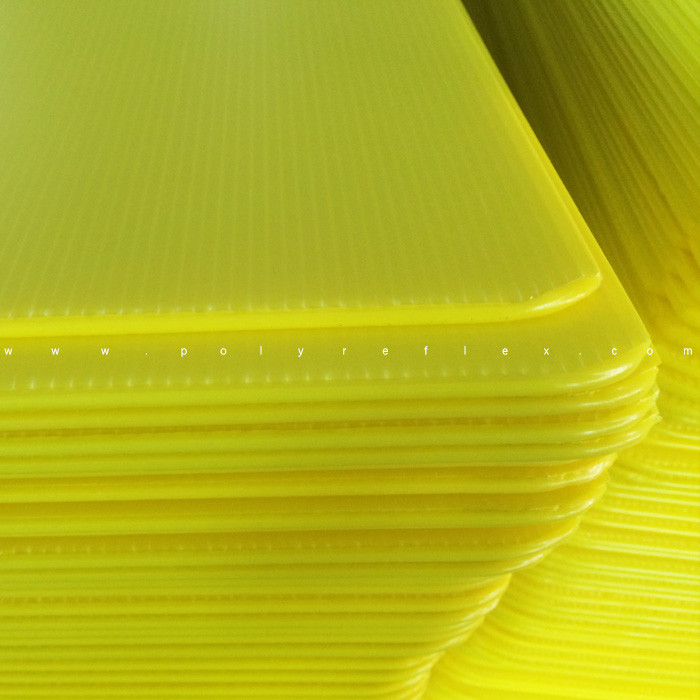

Enter PP corrugated sheets, a plastic alternative that is quickly gaining favor among beverage manufacturers and distributors. This article compares PP corrugated sheets and cardboard in beverage transportation to help businesses make informed decisions on their packaging materials.

Material Overview: Cardboard vs PP Corrugated Sheets

Before diving into performance differences, it's important to understand the basic characteristics of each material:

Feature | Cardboard | PP Corrugated Sheet |

Water Resistance | Poor | Excellent |

Reusability | Single-use | 20+ reuse cycles |

| Impact Resistance | Moderate | High |

| Durability | Susceptible to wear | Long-lasting |

| Recyclability | Recyclable | 100% recyclable |

Initial Cost | Low | Slightly higher |

| Cost per Use | High (single use) | Lower over time |

Perform ance Comparison in Beverage Transportation

1. Moisture and Water Resistance

Cardboard absorbs moisture easily, which leads to warping, weakening, or collapse—especially during cold-chain transportation or when exposed to condensation from chilled beverages. In contrast, PP corrugated sheets are waterproof and unaffected by humidity, making them ideal for wet environments and refrigerated trucks.

2. Load-Bearing and Impact Strength

Beverage crates often carry heavy bottles or cans. Cardboard’s structural integrity degrades quickly under pressure or repeated handling. PP corrugated sheets offer higher tensile strength and impact resistance, ensuring that even under heavy loads, the packaging remains stable and protective.

3. Stacking Stability

When stacking crates or pallets, stability is crucial. A warped or softened cardboard sheet can cause slippage or toppling. PP corrugated sheets maintain their shape and rigidity even after repeated use, supporting secure and stable stacking.

4. Reusable Cycles and Longevity

Unlike cardboard, which is typically single-use, PP corrugated sheets can be reused over 20 times or more, depending on application and handling. This drastically reduces the number of materials needed over time and improves operational efficiency.

Sustainability and Cost Efficiency

While PP corrugated sheets may have a higher upfront cost compared to cardboard, their long-term benefits result in lower cost per use. One PP sheet can replace dozens of cardboard inserts or liners, reducing waste and replacement frequency.

Additionally, PP sheets are 100% recyclable. They can be collected, cleaned, and reprocessed into new plastic products. Many beverage companies are choosing PP corrugated solutions as part of their sustainability initiatives to reduce environmental impact and meet stricter ESG goals.

When to Choose PP Corrugated Sheets over Cardboard?

Choose PP corrugated sheets if your beverage transportation involves:

Cardboard may still be suitable for low-risk, single-use, or ultra-low-cost applications, but for demanding or reusable logistics scenarios, PP corrugated sheets are the superior option.

PP corrugated sheets offer a modern, durable, and environmentally friendly alternative to cardboard in beverage packaging and transportation. With better performance in wet environments, longer lifespan, and excellent cost-efficiency, they’re an ideal solution for forward-thinking beverage brands and distributors.

As a professional manufacturer with 18 years of experience, Polyreflex provides high-quality, customizable PP corrugated sheets designed specifically for beverage industry needs. Whether you're looking to improve load stability, reduce waste, or enhance hygiene, we have the solution for you.

Ready to upgrade your beverage packaging?

Contact Polyreflex today for a free consultation, custom design options, or to request product samples.

Email us at: sale@polyreflex.com

Learn more: www.polyreflex.com